ASTM D1160 Distillation Of Petroleum Products At Reduced Pressure

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets one month

The sample is distilled at an accurately controlled pressure between 0.13 and 6.7 kPa (1 and 50 mm Hg) under

conditions that are designed to provide approximately one theoretical plate fractionation. Data are obtained from which the initial boiling point, the final boiling point, and a distillation curve relating volume percent distilled and atmospheric equivalent boiling point temperature can be prepared.

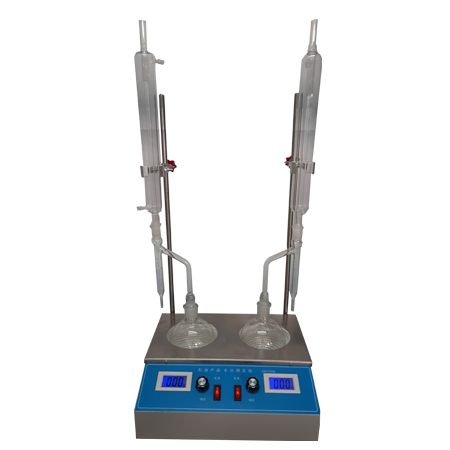

KN-1160 Vacuum Distillation Apparatus

Overview

KN-1160 Vacuum Distillation Apparatus conforms to the ASTM D1160 StandardTest Method for Distillation of Petroleum Products at Reduced Pressure. It is used for measuring at reduced pressures, of the range of boiling points for petroleum products and biodiesel that can be partially or completely vaporized at a maximum liquid temperature of 400°C.The apparatus consists of distillation column, pressure detecting system, receiver cabin, vacuum pump, cold trap, refrigeration unit, press and etc.

Features

1.High precision thin diaphragm vacuum differential pressure gauge replaces hydrargyrum differential pressure gauge

2.Digital LCD displays pressure result clearly

3.High precision needle valve control pressure

4.Temperature display: digital display temperature controller

5.PID temperature control technology makes the temperature more accurate, precision within ±0.1℃

6.Pressure range: 760mmHg~0.1mmHg

7.Portable-type electric furnace regulation device, easy operation

8.The receiver is equipped with flow nappe, which makes flow rate more equal.

Technical Parameters

1.Applicable standards: ASTM D1160 ISO6616

2.Heating power: 1200W

3.Temperature sensor: Glass Pt100

4.Pressure display: Digital display

5.Pressure adjustment method: Precision needle valve

6.Cooling temperature: Below -45℃

7.Cooling method: Imported compressor refrigeration

8.Water level control: Alarm

9.Temperature control method: PID precision temperature control instrument

10.Cycle method: Circulating method11.Cooling mode: Air cooling