-

ASTM D2170 Viscosity Of Asphalts By Vacuum Capillary Viscometer

the kinematic viscosity characterizes flow behavior. the method is used to determine the consistency of bitumen as one element in establishing the uniformity of shipments or sources of supply. the specifications are usually at temperature of 60 and 135℃.

Send Email Details -

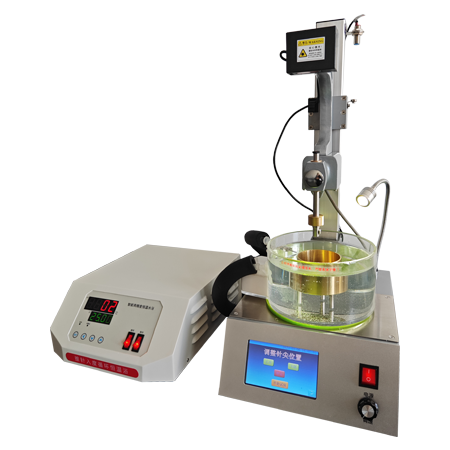

ASTM D2171 Apparatus for Viscosity of Asphalts

KN-2171 Apparatus for Viscosity of Asphalts conforms to ASTM D2171 Standard Test Method for Viscosity of Asphalts by Vacuum Capillary Viscometer. The viscosity at 60℃ characterizes flow behavior and may be used for specification requirements for cutbacks and asphalt binders. This time is measured for a fixed volume of the liquid to be drawn up through a capillary tube by means of vacuum, under closely controlled conditions of vacuum and temperature. The viscosity in Pascal-seconds is calculated by multiplying the flow time in seconds by the viscometer calibration factor.

Send Email Details -

ASTM D5 Penetration Of Bituminous Materials

the penetration test is used as a measure of consistency.higher values of penetration indicate softer cnssistency

Send Email Details -

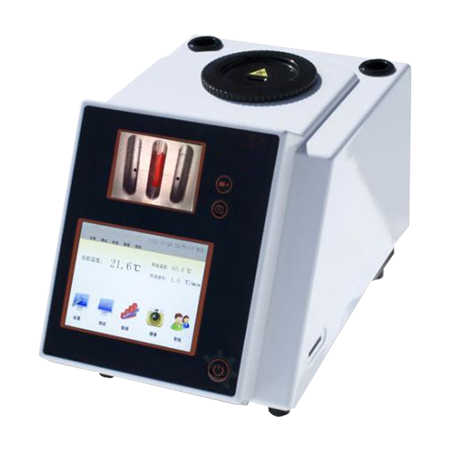

ASTM D87 Automatic Petroleum Wax Melting Point Apparatus

KN-87Z Automatic Petroleum Wax Melting Point Apparatus (Cooling Curve Method) conforms to ASTM D87 Standard Test Method for Melting Point of Petroleum Wax (Cooling Curve), it covers the determination of the melting point (cooling curve) of petroleum wax. It is unsuitable for waxes of the petrolatum group, microcrystalline waxes, or blends of such waxes with paraffin wax or scale wax.

Send Email Details -

ASTM D938 Congealing Point of Petroleum Waxes and Petrolatum

KN-938 Congealing Point of Petroleum Waxes and Petrolatum conforms to ASTM D938 Standard Test Method for Congealing Point of Petroleum Waxes, Including Petrolatum. Congealing point is a wax property that is of interest to many petroleum wax consumers. The procedure described here measures the temperature at which a sample being cooled develops a “set” or resistance to flow. At that temperature, the wax may be at or close to the solid state, or it may be semisolid and quite unctuous, depending on the composition of the wax or petrolatum being tested. In the case of petrolatums, congealing property is associated with the formation of a gel structure as the sample cools. A sample of wax is melted and a droplet is made to adhere to the bulb of a thermometer. Using a prewarmed flask as an air jacket, the droplet on the bulb is allowed to cool at a fixed rate until it congeals. The congealing point is observed as the temperature at which the droplet ceases to flow as the thermometer is turned.

Send Email Details -

ASTM D127 Petroleum Wax Drop Melting Point

Melting point is a wax property that is of interest to most wax consumers. It can be an indication of the performance properties of the wax. Drop melting point, Test Method D127, is often used to measure the melting characteristics of petrolatums and other high viscosity petroleum waxes

Send Email Details -

ASTM D721 Oil Content Of Petroleum Waxes

The oil content of a wax may have significant effects on several of its properties, such as strength, hardness, flexibility, scuff resistance, coefficient of friction, coefficient of expansion, melting point, and oil straining. The importance of these effects may be dependent upon the ultimate use of the wax

Send Email Details -

ASTM D2872 Rolling Thin Film Oven Test

this oven indicates approximate change in properties of asphalt during conventional hot-mixing ar about 150℃ as indicated by viscosity and other rheological measurements.it yields a residue which approximates the asphalt condition as incorporated in the pavement.if the mixing temperature differs appreciably from the 150℃ level. more or less effect on properties will occur. this oven also can be used to determine mass change,which is a measure of asphalt volatility

Send Email Details -

ASTM D88 Asphalt Saybolt Viscometer

KN-88 Asphalt Saybolt Viscometer is designed and made as ASTM D88 Standard Test Method for Saybolt Viscosity. It covers the empirical procedures for determining the Saybolt Universal or Saybolt Furol Viscosities of petroleum products at specified temperatures between 21 and 99℃ (70 and 210℉).

Send Email Details -

ASTM D4402 Rotational Viscometer for Asphalt Viscosity

KN-4402 Rotational Viscometer for Asphalt Viscosity conforms to ASTM D4402 Standard Test Method for Viscosity Determination of Asphalt at Elevated Temperatures Using a Rotational Viscometer. A rotational viscometer is used to measure the apparent viscosity of asphalt at elevated temperature. The torque on the apparatus-measuring geometry, rotating in a thermostatically controlled sample holder containing a sample of asphalt, is used to measure the relative resistance to rotation. The torque and speed are used to determine the viscosity of the asphalt in pascal seconds, millipascal seconds, or centipoise.

Send Email Details -

ASTM D36 Automatic Bitumen Softening Point of Asphalt (Ring-and-Ball)

KN-36 Apparatus for Softening Point of Asphalt (Ring-and-Ball Test apparatus) conforms to the ASTM D36 Standard Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus). The apparatus covers the determination of the softening point of bitumen in the range from 30 to 160°C [86 to 320°F] using the ring-and-ball apparatus immersed in distilled water [30 to 80°C] or USP glycerin (above 80 to 160°C).

Send Email Details