ASTM D1266 Sulfur In Petroleum Products Lamp Method

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets one month

The sample is burned in a closed system, using a suitable lamp (Fig. 1) and an artificial atmosphere composed of

70 % carbon dioxide and 30 % oxygen to prevent formation of nitrogen oxides. The oxides of sulfur are absorbed and oxidized to sulfuric acid by means of hydrogen peroxide solution which is then flushed with air to remove dissolved carbon dioxide. Sulfur as sulfate in the absorbent is determined acidimetrically by titration with standard sodium hydroxide solution, or gravimetrically by precipitation as barium sulfate

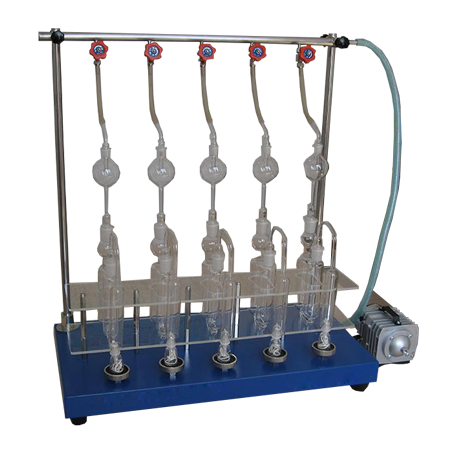

KN-1266 Sulfur Lamp Method Unit

Overview

KN-1266 Sulfur Lamp Method Unit conforms to the ASTM D1266 Standard Test Method for Sulfur in Petroleum Products (Lamp Method). This apparatus covers the determination of total sulfur in liquid petroleum products in concentrations from 0.01 to 0.4 mass %. A special sulfate analysis procedure permits the determination of sulfur in concentrations as low as 5 mg![]() .

.

KN-1266:5 flasks

KN-1266A:7 flasks

Features

1. The apparatus structure is unified,be equipped with 5 tubes,7 tubes devices, improves working efficiency.

2. The glassware stand adopts organic glass pane, safe and reliable.

3. The apparatus adopts high quality lamp and needle valve

4. The apparatus adopts stainless steel pipeline and standard glass bead

5. The pedestal of burning lamp is equipped with lift adjusting device,easy to be adjusted.

6. The apparatus adopts sucking pump, small in size and low in noise.

7. Easy operation with rational construction and attractive appearance.

Technical parameters

1.Rated voltage: AC220V±10% 50Hz

2.Glassware components:5 tubes(7 tubes)

3.Sucking pump: 220V 60W

4.Ambient requirements:Temperature: 10~40℃;Humidity≤85%