ASTM D3237 Lead in Gasoline by AAS

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets one month

The gasoline sample is diluted with methyl isobutyl ketone and the alkyl lead components are stabilized by reaction with iodine and a quaternary ammonium salt. The lead content of the sample is determined by atomic absorption flame spectrometry at 283.3 nm, using standards prepared from reagent grade lead chloride. By the use of this treatment, all alkyl lead compounds give identical response.

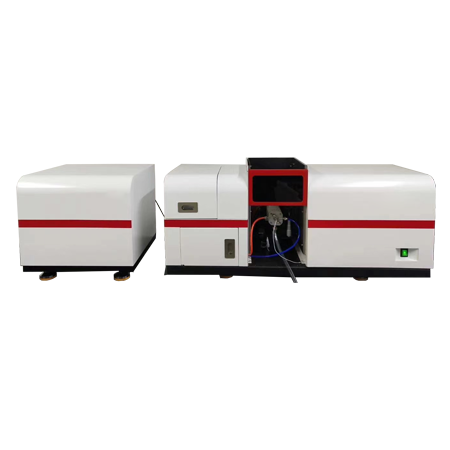

KN-3227 Lead in Gasoline by AAS

Overview

KN-3227 Lead in Gasoline by AAS conforms to ASTM D3237 Standard Test Method for Lead in Gasoline by Atomic Absorption Spectroscopy. This AAS covers the determination of the total lead content of gasoline within the concentration range of 0.010 to 0.10 g of lead/U.S. gal (2.5 to 25 mg/L). This tester compensates for variations in gasoline composition and is independent of lead alkyl type.

The products include the flame, graphite furnace and hydride generation system, which can be equipped with various accessories, flexible configuration program can meet different customer demand. KN-3237 atomic absorption spectrometer can be used for analysis of complex samples, full automatic multifunctional, various analysis methods can automatically switch, unmanned automatic analysis.

Main features

High precision automatic optical system

1800 / mm reticle (dispersion rate) large area grating monochromator, a new type self collimation, all lenses are quartz coating, the detection range and the stability of optical broad to ensure the precision of analysis. Automatic 6 socket configuration six independent lamp power supply, can be respectively preheating

Polymer spray chamber

Polymer materials corrosion spray chamber, acid and alkali resistance, including hydrofluoric acid, either organic or inorganic solution can be the highest sensitivity and stability

Titanium burner

Titanium burner, the optional 50mm and 100mm burner, air cooling pre mixed type, corrosion resistant, resistant to high salt, greatly improve the analysis efficiency and accuracy of the flame

Automatic analysis

It can automatically accomplish safety ignition, extinction and switching, reliable structure, low fault rate, thus ensuring the sensitivity and reproducibility of the flame method.

The light source system six lamp automatic conversion, can be directly used high performance hollow cathode lamp, improve the sensitivity analysis of the flame, the automatic adjustment of the power supply parameters and the beam position, automatic wavelength scanning and searching peak

Software function

High intelligent software, powerful function, friendly interface English operation. Automatic instruments and additional control, flame, graphite furnace operating mode can be switched automatically, automatic optimization, automatic dilution; mouse operation, automatic setup menu data and correction method

Graphite furnace temperature control

Gas dual temperature control inside and outside, 20 order linear or nonlinear heating, to ensure that the measured elements has the highest sensitivity; furnace enriched up to 20 times, the longitudinal optically monitoring the graphite tube wall temperature, maximum temperature to 3000 degrees centigrade.

High technology index

KN-3237 atomic absorption spectrophotometer elements test sensitivity meet international best level, sensitivity of less than or equal to0.015μg/mL/1%; baseline drift is less than 0.003Abs/30m, the stability is better than 0.005Abs/4h

Background correction system

Using deuterium hollow cathode lamp advanced and self absorption background deduction of background correction, to eliminate the interference of molecular absorption of low content determination, reducing the noise emission of deuterium lamp and prolongs the service life, has excellent stability. Deuterium lamp background signal for 1A, background correction ability > 50 times

Intelligent analysis

Great intelligence, humanized design, flame and graphite furnace atomizer automatic switching, automatic optimization of graphite furnace atomizer, automatically set the flame height adjustment, automatic ignition, automatic optimization of the horizontal position, system automatically sets the gas flow. In the case of power failure, misoperation, acetylene leakage, the system will automatically start the safety protection function

Automatic sampler

Integrative design of graphite furnace, using high precision syringe, lowest in 0.5μl samples, with intelligent online dilution and concentration function.

Technical parameters

Mainframe | ||

Model | : | KN-3227 |

Light Source | : | ≤6 lamps automatic turret, automatic alignment |

Power Supply | : | 110/220V (+5% ~ -10%), 60/50Hz; 5000VA |

Lamp Current | : | pulsed power supply |

Optical System | : | large 1800 /mm grating ruling, full closed optical system |

Wavelength Range | : | 180nm-900nm |

Automatically peak find a key optical optimization function | ||

Wavelength Accuracy | : | ≤0.15nm |

Wavelength Repeatability | : | ±0.1nm |

Spectral Bandwidth | : | 0nm、0.2nm、0.4nm、1.0nm、2.0nm |

(5 steps with automatic changeover) | ||

Baseline Stability | : | ≤±0.002A/30 min (Static) |

≤±0.005A/30min (Dynamic) | ||

Absorbance Range | : | 0-4A |

Flame Analytical System | ||

Detector | : | imported photomultiplier tube |

Burner Head | : | full titanium combustion head, 50mm or 100mm general combustion head |

Atomization Chamber | : | polymer explosion-proof spray chamber |

Nebulizer | : | atomizer efficient glass atomizer, can also be customized |

Ignition Type | : | microcomputer control, automatic ignition |

Gas Control | : | automatic gas control system |

Detection Limits(Cu) | : | 0.002μg/mL |

Precision | : | RSD≤0.5% |

Graphite Furnace Analytical System | ||

Heating Mode | : | vertical heating |

Temperature Control Method | : | vertical optical temperature monitoring graphite tube wall temperature |

Temperature Range | : | room temperature to 3000℃ |

The Program | : | automatic temperature control up to 20 order |

Temperature Control | : | the furnace enriched up to 20 times |

Characteristics Volume | : | 0.5 × 10-12g (Cd) |

Detection Limit | : | 0.4 × 10-12g (Cd) |

Precision | : | RSD≤3% |

The Cooling Water | : | can choose cooling water circulation system |

Safety | : | the graphite tube damage, water flow |

air pressure and other alarmtemperature overheating protection | ||

Autosampler Graphite Furnace | ||

Sample Tray | : | 70 sample cups, 6 reagent cup |

Sample Volume | : | 1-100μl |

The Smallest Lincrement | : | 0.1 μl |

The Volume of Sample | : | better than 1%(at the time of 10mL-100mL) |

Repeatability Volume | ||

Repeated Sampling Frequency | : | up to 99 Times |

Cleaning and Waste | : | each 500mL |

Container Volume | ||