ASTM D6667 Ultraviolet Fluorescence Sulfur Content For LPG

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets one month

The sulfur content of LPG, used for fuel purposes, contributes to SOx emissions and can lead to corrosion in

engine and exhaust systems. Some process catalysts used in petroleum and chemical refining can be poisoned by sulfur bearing materials in the feed stocks. This test method can be used to determine sulfur in process feeds, to measure sulfur in finished products, and can also be used for compliance determinations when acceptable to a regulatory authority

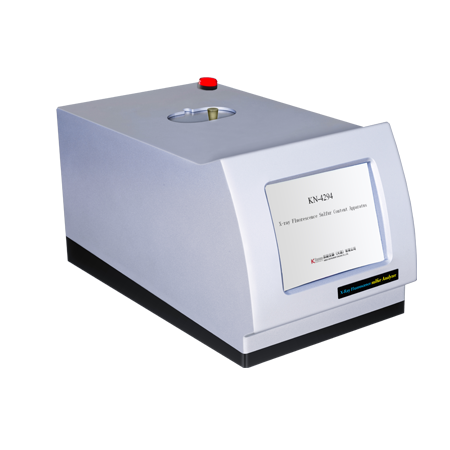

KN-6667 Ultraviolet Fluorescence Sulfur Tester for LPG

Overview

KN-6667 Ultraviolet Fluorescence Sulfur Tester for LPG adopts advanced total sulfur analysis method--ultraviolet fluorescence method, determine the total sulfur content of various kinds of gas, liquid, solid oils and chemical product. It is a apparatus with high sensitivity, stable property, low detection lower limit, accurate test result, good repeatability. The apparatus conforms to the ASTM D6667.

Feature

We adopts the most advanced ultraviolet lamp and other critical components to ensure the super high sensitivity and reliability.

Adopts the imported American Nafion pipe membrane dryer, good water removal to ensure the stability apparatus

The apparatus can establish and store the working curve, user can make the specimen analysis without establishing the working curve again.

By selecting the gas smple injector or the solid sample injector, the apparatus can make the analysis of gas, liquid and solid sample to meet various tests

Windows interface, convenient to operate

Equipped with LPG sampler.

Technical Parameters

Specimen species: liquid, solid and gas specimen

Measurement method: ultraviolet fluorescence

Specimen sample size: solid sample size: 1~20mg

liquid sample size: 1~30μL

gas sample size: 1~10 mL

Measurement range: 0.2 mg/L~3%

Detection lower limit: 0.2 mg/L

Temperature control range: room temperature to 1100℃

Temperature control precision: 0.5%±2℃

Gas source requirement: argon: above 99.995% ,oxygen: above 99.99%, humidity<5%

Rated voltage: AC220V±22V 50Hz±0.5Hz

Power: 1500W