ASTM D892 Foaming Characteristics Of Lubricating Oils

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets one month

The tendency of oils to foam can be a serious problem in systems such as high-speed gearing, high-volume pumping, and splash lubrication. Inadequate lubrication, cavitation, and overflow loss of lubricant can lead to mechanical failure. This test method is used in the evaluation of oils for such operating conditions.

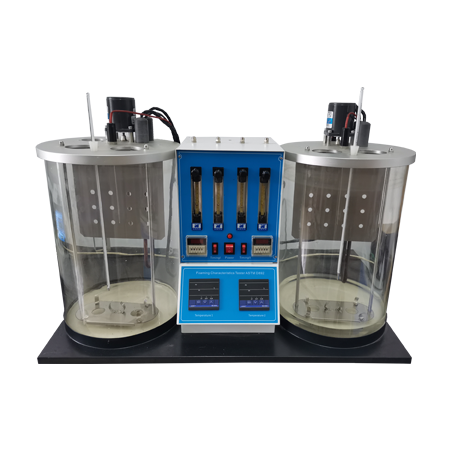

KN-892 Anti Foam Test for Lubricating Oil

Overview

KN-892 Anti Foam Test for Lubricating Oil conforms to ASTM D892 Standard Test Method for Foaming Characteristics of Lubricating Oils, the apparatus is used for testing the foaming characteristics of lubricating oils at 24°C and 93.5°C. Means of empirically rating the foaming tendency and the stability of the foam are described.

Features

The digital display temperature controller features flexible operation and high precision.

The heating output adopts solid-state relay, contactless, sparkless, noiseless. Long life time, safe and reliable.

The heater adopts stainless steel material. The heating rate is fast and the life time is long.

The apparatus is equipped with two holes, can do two groups of parallel sample experiments, improve work efficiency.

The apparatus is equipped with four groups of flow meters, convenient to observe the flow of experimental gas.

Rational design with attractive appearance and friendly to the environment.

Technical parameters

Rated voltage:AC220V±10% 50Hz

Power:2500W

Temperature controlling mode: Digital Display

Temperature controlling point:24°C, 93.5°C

Temperature controlling precision:±0.5°C

Sensor:Pt100

Hole of the bath:2 holes

Agitation mode: electrical machine 1250turns/min

Ambient requirements: Temperature 10~40°C; Humidity≤85%