EN14214 Fatty Acid Methyl Esters For Biodiesel By GC

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets one month

The biodiesel specified shall be mono-alkyl esters of long chain fatty acids derived from vegetable oils and animal fats.

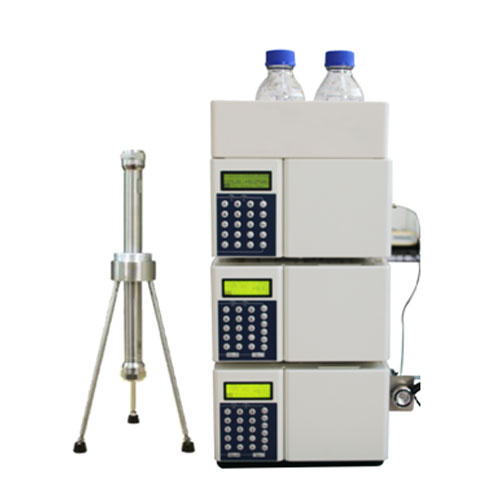

KN-Biodiesel GC Plus Gas Chromatograph

Introduction

Interest in biodiesel as a clean-burning alternative fuel produced from renewable sources such as vegetable oils has increased tremendously over the last few years, mainly due to its reduced environmental impact in comparison with conventional petro-diesel. Biodiesel can be used as a pure fuel or blended at any level with petroleum diesel. In order for biodiesel to be commercialized as pure biofuel or blending stock for heating and diesel fuels, it must meet a set of requirements defined in ASTM D6751 and EN 14214 standard specifications. These standards indicate the maximum allowable concentrations of contaminants in pure (B100) finished product, along with other chemical-physical properties necessary for a safe and satisfactory engine operation.

ASTM D6584 Standard Test Method for Determination of Total Monoglyceride, Total Diglyceride, Total Triglyceride, and Free and Total Glycerin in B-100 Biodiesel Methyl Esters by Gas Chromatography

EN14103 Fat and Oil Derivatives-fatty acid methyl esters FAME determination of ester and linolenic acid methyl ester contents

EN14110 Fat and oil derivatives - Fatty Acid Methyl Esters (FAME) - Determination of methanol content

Instrumentation and Reagents

The analysis of glycerin, mono, di and triglycerides by gas chromatography (GC) requires a non-discriminative injection system able to transfer both volatile and heavy compounds without discrimination or degradation. A TRACE GC Ultra equipped with a true cold On-column inlet and a flame ionization detector (FID), automated by a TriPlus Autosampler for liquids was used, controlled through the Thermo Scientific Chrom-Card data system. The true cold On-column injector offered on the TRACE GC Ultra is a permanently cold system, able to prevent discrimination of the heavier fraction and to eliminate any risk of degradation of labile components like triglycerides, thus granting excellent recovery and proven sample integrity.

The analytical column used is a non-polar Thermo Scientific TRACE™ TR-BIODIESEL(G), 10 m, 0.32 mm ID, 0.1 μm f.t. This column is designed to provide excellent performance for this high temperature GC method, featuring enhanced mechanical robustness at high oven temperature, and thus prolonged lifetime. A 1 m x 0.53 mm ID pre-column is used, connected to the column by a leak-free high T purged connection.

A low dead volume leak-free metal tee has been specifically conceived for a reliable connection between the guard column and the analytical column at high temperature operation, preventing from the use of normal glass press-fit unions. Such a connector has proven to stay leak-free even with extremely large and frequent oven temperature variations (Figure 2).

Calibration is achieved by the use of two internal standards – 1,2,4-butanetriol (IS1) for glycerine and tricaprin (IS2) for mono-, di- and tri-glycerides, and four reference compounds – glycerin, mono-olein, di-olein and tri-olein.

Because glycerin and mono- and di-glycerides are polar and high boiling components, they must be derivatized to increase their volatility and reduce activity before injection into the GC. The method requires derivatization with MSTFA (N-methyl-N-trimethylsilyltrifluoroacetamide) in pyridine, which transforms these compounds into more volatile silylated derivatives. Below is a list of required reagents:

• MSTFA (N-methyl-N-trimethylsilyltrifluoroacetamide)

• n-Heptane

• Pyridine

• 1,2,4-Butanetriol – internal standard solution 1,1 mg/mL in pyridine (IS1)

• 1,2,3-Tricaproylglycerol (tricaprin) - internal standard solution 2, 8 mg/mL in pyridine (IS2)

• Reference materials: glycerol (glycerin), 1-monooleoylglycerol (monoolein), 1,3-di-oleolglycerol (diolein), 1,2,3-tri-oleoylglycerol (triolein)

• Mono-glycerides check mix (monopalmitin, monostearin and monoolein), in pyridine Figure 2: Leak free high T purged connector

Main Features

KN-GC-9600 Plus adopts 10.2 inch touch LCD. It can display the temperature of each way and Real-Time Operation conditions, so as to achieve the on line monitoring

POST, independent temperature control of six ways and five stages program temperature rise

Self-diagnosis function: If there is a failure, the apparatus will automatic display the fault phenomenon, code and cause to help the operator find and solve the fault in short time

Over temperature protection: The protective temperature can be set freely, if there is a way exceeds the setting temperature, the apparatus will automatic power off and alarm

Carrier gas protection: When the carrier gas is under pressure, the apparatus will automatic power off and stop heating to protect chromatographic column and thermal conductivity detector effectively

Intelligent fuzzy control back gate system: Automatic tracing temperature and dynamic regulate the angle of the back gate. The apparatus can do precision control under room condition.

Equipped with packed column chapiter sampling, glass-lined sampling and capillary split/splitless sampling device with membrane cleaning function. The apparatus also can install the gas sampler

High precision and stable dual way. Maximum can install 4 kinds of detector

Advanced gas routine, it is available to use hydrogen flame detector and thermal conductivity detector.

Both FID and capillary tube inlet are EPC controlled

Electronic flow pressure display system and internal work station device can be selected

19 digits automatic liquid sampler

Technical Parameters

Temperature control index

1. Temperature control range:Room temperature 5℃~400℃, Increment: 0.1℃

2. Temperature control accuracy: Better than ±0.1℃

3. Temperature programming: 5 stages, constant temperature time between stage:0~999min

Increment:0.1min,Temperature increment: 0.1℃

Heating rate: Maximum 40℃/min below 200℃

Maximum 20℃/min above 200℃

LOD

Compound | Max % m/m (EN 14214) |

Glycerin | 0.02 |

Mono-glycerides | 0.8 |

Di-glycerides | 0.2 |

Tri-glycerides | 0.2 |

Total Glycerin | 0.25 |