Four Ball Wear Tester

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets one month

This test method, used for specification purposes, differentiates between lubricating fluids having low, medium, and high level of extreme-pressure properties. The user of this method should determine to his own satisfaction whether results of this test procedure correlate with field performance or other bench test machines.

KN-2783Z Automatic Four Ball Wear Tester

Overview

KN-2783Z Automatic Four Ball Wear Tester is used to test the Wear Preventive (WP) and Extreme Pressure (EP) characteristics of greases and lubricating oils in sliding steel-on-steel applications. It conforms to the ASTM D2783, ASTM D2266 and ASTM D4172 Standard Test Method for Wear Preventive Characteristics of Lubricating Fluid (Four-Ball Method).The tester adopts sliding friction, under the high point contact pressure, to evaluate the carrying capacity of the lubricant. It includes the maximum no seizure load PB, sintering load PD and composite wear value ZMZ three items indexes. The tested is also used for the long-time abrasion resistance tests, to measure the friction coefficient.

Features

-

The tester is used to evaluate the friction and wear performance of the end face, pin plate and other samples in the form of sliding friction at room temperature and high temperature.

-

Be able to evaluate the friction and wear performance of various metals, engineering plastics, ceramics and powder metallurgy and other new materials, determine the wear resistance of materials and material matching characteristics, and test under various parameters such as variable load, speed, friction pair, and test environment temperature.

-

The application of the test force is controlled by a hydraulic closed-loop servo system, and the test force is set by the operator on the computer interface.

-

The spindle speed, number of revolutions, test force, friction torque, friction pair temperature, test time and other parameters are controlled by the computer, which can collect test data in real time and draw the corresponding test curve, and can store, read, and print out test data or curves at will.

-

Equipped with total of 10 kinds of friction pairs, to meet different demands.

-

The main spindle drive is controlled by AC servo motor and control system, and the high-speed torque accuracy of the motor is less than than 0.2%, which can realize stepless speed regulation and constant torque output within the required speed range, and the speed control accuracy is high, and low-speed output can be realized.

-

Computer and data processing system: embedded computer, industrial control module and corresponding measurement and control software, to do the whole process of control of the whole machine and the test process, software interface visualization, real-time control and display of various parameters, automatic recording and display of various kinds of curves, such as friction coefficient - time curve, temperature - time curve, test force - time curve, speed - time curve, etc.

-

Free software update if there is any updates

Main parameters and index

-

Test force range (stepless adjustable) 50N~10000N, Error within ±1%

-

Max friction force: 1000N±2%

-

Friction force torque measuring range: 0~15Nm, automatic display the saved value

-

Main spindle speed: 1~3000rpm±1rpm, servo stepless adjustable

-

Temperature control range: Ambient~1000℃±2℃

-

Test medium: Air, Oil, Water, Mud and Grinding Material etc.

-

Time range: 1s~9999min

-

Stop method: Manual/Automatic (Time, Revolutions, Torque, etc.)

-

Oil chamber stroke>45mm

-

Main spindle power: 3Kw

-

Net dimension: 1200*870*1700mm

-

Net weight: 850kg

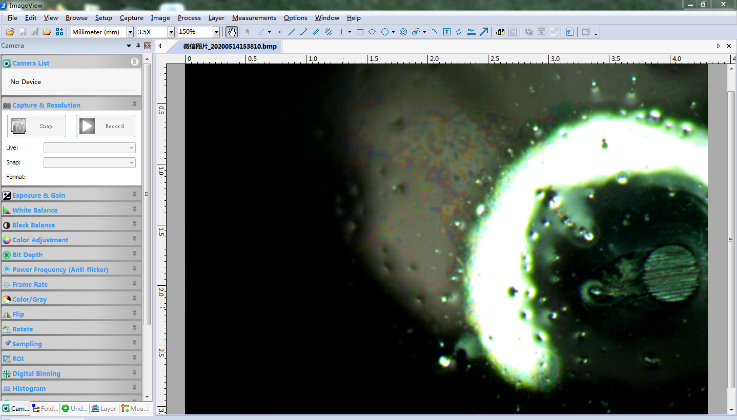

CCD Grinding Measurement System

A. Introduction

The grinding spot measurement system is specialized for the measurement of the grinding spot in the friction test. This machine is specially used for the measurement of four ball friction test machine, with all accessories, meet the measurement requirements of four ball standard test.

Physical picture, you order the same, subject to the physical object

B. Structure and working principle of the system

The system is composed of measuring software, microscope, steel ball holder holder, camera, computer and standard scale.

The grinding spot on the steel ball is imaged on the CCD sensor of the camera by the optical system. The CCD sensor converts the optical signal into a digital signal, and is transmitted to the computer through the USB connection. The computer measurement software reads the data and displays the image on the screen, and then the image can be measured and edited.

C. Main parameter

1. Image sensor (digital camera): 3 million pixels;

2. Image resolution: 16001200;

3. Measurement range: maximum: 4 mm;

4. Measurement error: ± 0.01mm;

5. Microscope host: MDS0754-D, four-ball machine dedicated; 1 piece;

6. Base: CD-3, including CD high temperature-room temperature oil box with a seat (can be customized non-standard oil box seat) 1 set;

7. Workbench: 1 SP 1-L type, with shadowless light source, 6V / 10W cold anti-halogen tungsten lamp, adjustable brightness.