FTIR Spectrometer for Lubricants

Brand KN

Product origin DALIAN

Delivery time 30 DAYS AFTER RECEIVING FULL PAYMENT

Supply capacity 30 sets/month

Lubricant oils exhibit various chemical changes during their life time. This starts by simple changes such a fuel dilution of the fuel used or the uptake of soot (ASTM E2412) from the combustion. Numerous chemical reactions with combustion products lead to oxidation (ASTM D7414), nitration (ASTM D7624) or sulfation (ASTM D7415) of the lubricant and can be summarized as degradation products. To enable cycle times known from modern lubricants a wide variety of additives are added. These additives are used up during operation.

KN-FTIR Spectrometer for Lubricants

Overview

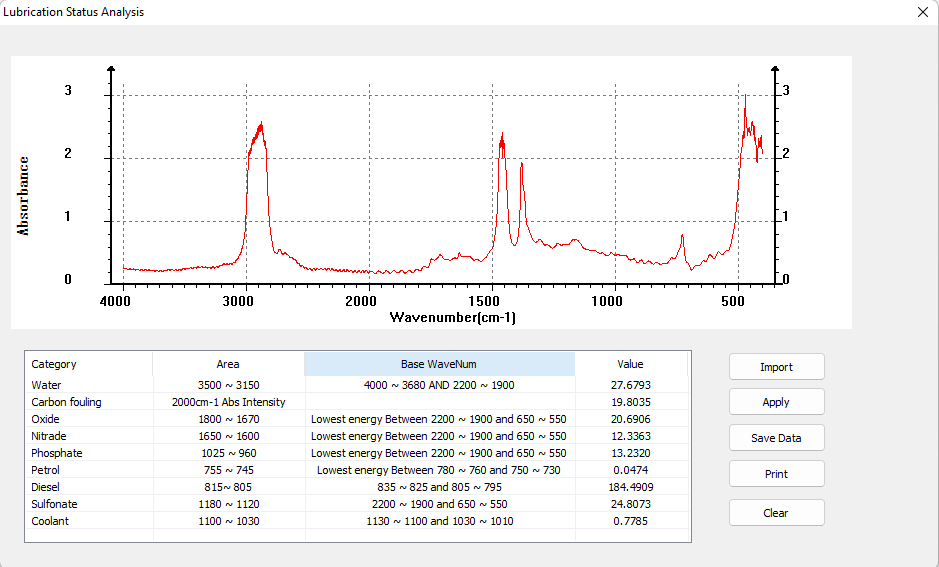

Lubricants are degraded by oxidation, consumption of additives, and accumulation of sludge. Because degradation of lubricants shortens the life of engines and causes operational problems, it is necessary to grasp the condition of degradation and carry out oil changes at the proper timing. The relevant ASTM standard provides a method for evaluating lubricants based on various parameters. It is possible to evaluate chemical changes such as oxidation, nitration, and sulfonation of lubricants and contamination by moisture and dust by KN-FTIR

KN-FTIR is a compact, robust and lightweight FTIR spectrometer, which can monitor the condition of lubricating oil and provide laboratory-grade results. The first truly self-contained infrared lube oil condition monitoring analyzer on the market today. Combines advantages such as fast and reliable test results and high portability. Can Test directly in the field, with results in seconds and in full compliance standard methods for ASTM, DIN and JOAP.

Grease Analysis with IR Spectroscopy (DIN 51820)

FTIR can be used to study the interaction between infrared electromagnetic radiation and chemical substances, with fast analysis speed, low dosage, and no damage to the sample. Using it to determine complex organic mixtures often yields accurate results, making it a highly effective analytical method in the study of lubricating greases. Various organic compounds such as thickeners, synthetic oils, and additives can be identified based on characteristic absorption spectra.

Lubricant Analysis with IR Spectroscopy

Lubricant oils exhibit various chemical changes during their life time. This starts by simple changes such a fuel dilution of the fuel used or the uptake of soot (ASTM E2412) from the combustion. Numerous chemical reactions with combustion products lead to oxidation (ASTM D7414), nitration (ASTM D7624) or sulfation (ASTM D7415) of the lubricant and can be summarized as degradation products. To enable cycle times known from modern lubricants a wide variety of additives are added. These additives are used up during operation.

Applicable field

Degradation | Standard | Unit |

Oxidation | ASTM E2412, D7414, JOAP, DIN 51453 | A/cm |

Nitration | ASTM E2412, D7624, JOAP, DIN 51453 | A/cm |

Sulfation | ASTM E2412, D7415, JOAP | A/cm |

Contaminants | Standard | Unit |

Soot | ASTM E2412, JOAP, DIN 51452 | A/cm, wt% |

Water | ASTM E2412, JOAP | A/cm, wt% |

Ethylene Glycol (Antifreeze) | ASTM E2412, JOAP | A/cm, wt% |

Diesel fuel | ASTM E2412, JOAP | A/cm, wt% |

Gasoline | ASTM E2412, JOAP | A/cm, wt% |

FAME | wt% | |

Polyol ester | wt% | |

Phosphate ester | wt% | |

Additives | Standard | Unit |

ZDDP | ASTM E2412, D7412, JOAP | A/cm, wt% |

Phenolic Antioxidants | ASTM D2668 | %, wt% |

Aminic Antioxidants | %, wt% | |

| Lubricating Grease | Standard | Unit |

| Thickeners | DIN 51820 | %, wt% |

| Synthetic oils | DIN 51820 | %, wt% |

| Additives | DIN 51820 | %, wt% |

High stable optical system

The design integrates main components to an optical bench machined from a cast aluminum. Highly stable and no need for adjustment, re-moving troubles of maintenance of optical path.

Precision machinery ensures high repeatability of every scanning. Advanced design concept is adopted in both optical path and every part

The system’s corner cube optics provides easy operation without requiring complicated electronics and additional moving parts. In addition, many components of the spectrometer are user replaceable that saves time over the lifetime of the instrument.

Internal dynamic collimation system and movable mirror driving system keep interferometer at optimum situation. Voice-coil driver and precision slide improves the ability of working in severe conditions.

The spectrometer includes a container of desiccant that protects the beam splitter and other optical components from moisture damage.

Working condition requirements

Ambient temperature: 16℃~25℃

Humidity range: 20% to 50%;

Power supply: AC100V ~ 240V, 47Hz ~ 63Hz 1.2A, good grounding

Technical parameters

Wavenumber range: 7800~350cm-1

Resolution: 1cm-1

Signal noise ratio: 30000:1 (DTGS, Resolution @ 4cm-1, sample and background scan for 1min @ 2100cm-1)

Detector: Pyroelectric detector

Beam splitter: Coated KBr

Light source: Long life, air cooled IR light source

Electronic system: A/D converter of 24 bits at 500MHz, USB 2.03

Power: 110V~220VAC, 50~60Hz

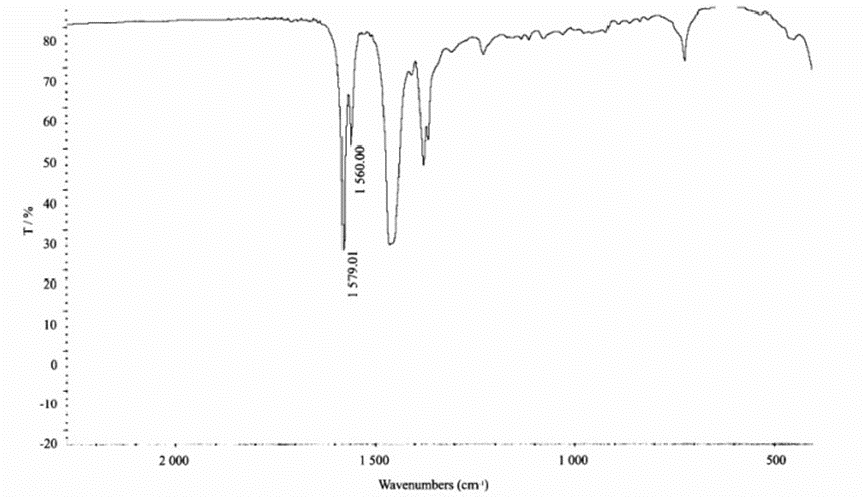

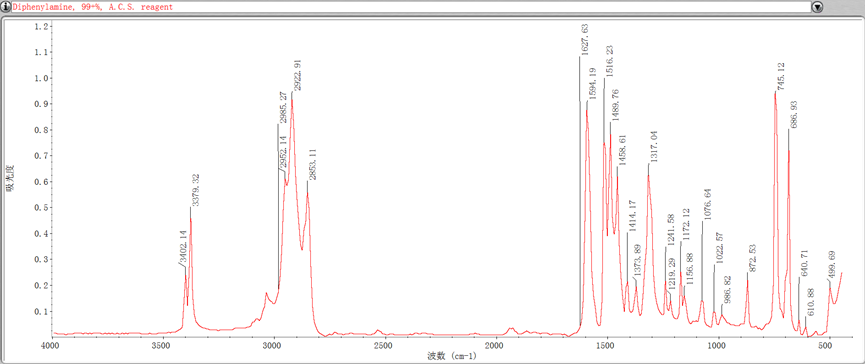

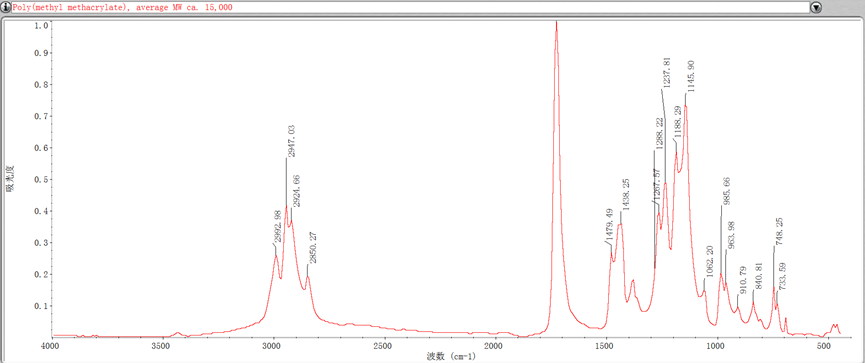

Typical element spectrum and curve

Lithium-based grease infrared spectrum

Diphenylamine infrared spectrum

Poly (Methyl Methacrylate) infrared spectrum

Packing list

Number | Item | Quantity |

1 | Spectrometer | 1 |

2 | Power supply | 1 |

3 | Dust cover | 1 |

4 | USB cable | 1 |

5 | Power cord | 1 |

6 | Screw driver, 150*6mm | 1 |

7 | Allen wrench, 2.5mm | 1 |

8 | Replacement desiccant | 1 |

9 | Polystyrene film | 1 |

10 | Software CD | 1 |

11 | User Manual | 1 |

Optional accessories

Number | Item | Specification | Mode | Quantity |

1 | Wedge shaped cell | 100μm Wedged ZnSe Flow cell | Specac | 1 |

2 | Drying oven | Used for placing infrared spectrometer | HW-9 | 1 |

3 | Special software | Oil condition analysis | S-IR-LOM | 1 |