ASTM D6481 Portable Energy Dissipation X-ray Fluorescence Spectrometer

Brand KN

Product origin DALIAN

Delivery time 30 DAYS AFTER RECEIVING FULL PAYMENT

Supply capacity 30 sets/month

KN-6481 Portable Energy Dissipation X-ray Fluorescence Spectrometer conforms to ASTM D6481 Standard Test Method for Determination of Phosphorus, Sulfur, Calcium, and Zinc in Lubrication Oils by Energy Dispersive X-ray Fluorescence Spectroscopy and ASTM D7751 Standard Test Method for Determination of Additive Elements in Lubricating Oils by EDXRF Analysis. This tester is used to test metal elements in oils like P, S, Cl, Ca, Ti, V, Cr, Mn, Fe, Ni, Cu Zn, PB, Mo, Ag, Cd, Sn, etc.

KN-6481 Portable Energy Dissipation X-ray Fluorescence Spectrometer

Overview

KN-6481 Portable Energy Dissipation X-ray Fluorescence Spectrometer conforms to ASTM D6481 Standard Test Method for Determination of Phosphorus, Sulfur, Calcium, and Zinc in Lubrication Oils by Energy Dispersive X-ray Fluorescence Spectroscopy, ASTM D7751 Standard Test Method for Determination of Additive Elements in Lubricating Oils by EDXRF Analysis, ASTM D4294 Standard Test Method for Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-ray Fluorescence Spectrometry and ASTM D5059 Standard Test Methods for Lead and Manganese in Gasoline by X-Ray Spectroscopy. This tester is used to test metal elements in oils like P, S, Cl, Ca, Ti, V, Cr, Mn, Fe, Ni, Cu Zn, PB, Mo, Ag, Cd, Sn, etc.

Features

1. Rugged, compact elemental analyzer for repeatable and reproducible results in laboratories production environments and mobile operations.

2. Intuitive interface is displayed on the large, industrial touchscreen

3. Streamlined software and one-touch measurement start makes it easy for any operator to get high quality results

4. Training for routine analysis takes only minutes

5. Atmospheric compensation allows analysis without the need for helium or vacuum purge, minimizing the cost per analysis

6. Automatic carbon/hydrogen (C/H) ratio correction allows the analysis of multiple types of oils and fuels to be made on a single calibration, simplifying analyzer setup and operation

7. X-ray tube and detector are operated in conditions designed to ensure long-term reliability

8. Built for tough environments

9. Software inspired by point-and-shoot hand-held analyzers

10. Entire display area is dedicated to routine analysis

11. One-touch measurement start for routine testing

12. On-board data storage of up to 100,000 results, including spectra

13. Low cost for maintenance

14. Easy sample preparation and user-friendly operation

15. No gas consumption or vacuum needed

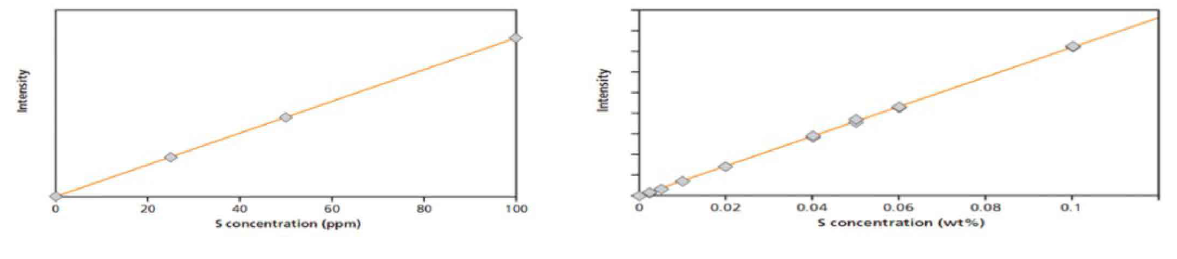

Working Curve Linear Chart

Technical Parameters

1. Factory calibration included

Low sulfur: 10ppm~100ppm

High sulfur: 0.01~5%

2. Dimension: 380*372*362mm

3. Fast SDD detector resolution proves the most excellent test performance

Area: 70mm²

Energy resolution: 130eV at Mn Kα

High Precision Results Without Daily Calibration is Needed

Unit: | PPM | Test Time: 100 seconds | ||

No. | Calibration | 300ppm | 1000ppm | 10000ppm |

1 | Crude Oil | 297 | 1001 | 10080 |

2 | Crude Oil | 293 | 998 | 9993 |

3 | Crude Oil | 305 | 1017 | 9982 |

4 | Crude Oil | 295 | 1008 | 9918 |

5 | Crude Oil | 291 | 1007 | 9978 |

6 | Crude Oil | 309 | 990 | 10068 |

7 | Crude Oil | 312 | 995 | 9986 |

8 | Crude Oil | 316 | 1015 | 9999 |

9 | Crude Oil | 307 | 1010 | 9918 |

10 | Crude Oil | 313 | 999 | 9928 |

11 | Crude Oil | 302 | 1016 | 9958 |

Certified Value | 300 | 1000 | 10000 | |

Average Test Result | 304 | 1005 | 9983 | |

Standard Deviation Sn | 8.64 | 9.10 | 53.96 | |

Error ppm | 4 | 5 | -17 | |

RSD | 2.85% | 0.91% | 0.54% | |