ASTM D6595 Rotary Disc Electrode Atomic Emission Spectrometer (ROE-AES)

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets one month

Wear metals and contaminants in a used oil test specimen are evaporated and excited by a controlled arc discharge using the rotating disk technique. The radiant energies of selected analytical lines and one or more references are collected and stored by way of photomultiplier tubes, charge coupled devices or other suitable detectors. A comparison is made of the emitted intensities of the elements in the used oil test specimen against those measured with calibration standards.

KN-6595 Rotary Disc Electrode Atomic Emission Spectrometer (ROE-AES)

Overview

KN-6595 Rotary Disc Electrode Atomic Emission Spectrometer (ROE -AES) which is capable of directly testing the contents of various metallic elements in liquid samples, such as lubricating oil, hydraulic oil, fuel oil, and etc., and finishing the analysis of various elements with a single injection with a single injection within 2 minutes. No sample pretreatments, auxiliary gas or cooling water is needed before and during the instrument is operating. Because of the strong adaptability to the environment, this instrument can be operated in warship or in the field. The instrument conforms to the ASTM D6595 Standard Test Method for Determination of Wear Metals and Contaminants in Used Lubricating Oils or Used Hydraulic Fluids by Rotating Disc Electrode Atomic Emission Spectrometry and ASTM D6728 Standard Test Method for Determination of Contaminants in Gas Turbine and Diesel Engine Fuel by Rotating Disc Electrode Atomic Emission Spectrometry.

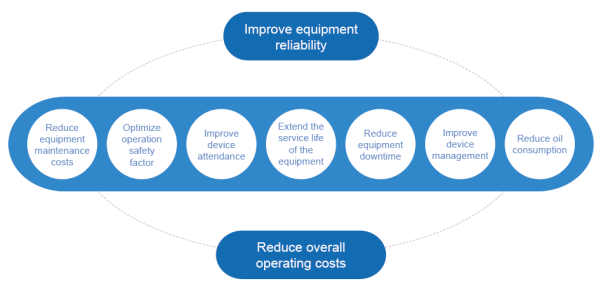

The instrument can be widely used in fields of oil quality monitoring for large equipment, such as aircrafts, warships, high-speed railways, engineering machinery, and etc. It can be applied to the monitoring of mechanical wear and fault diagnosis analysis. It is commonly applied to the field of metallic elements analysis in oil.

Technical principle

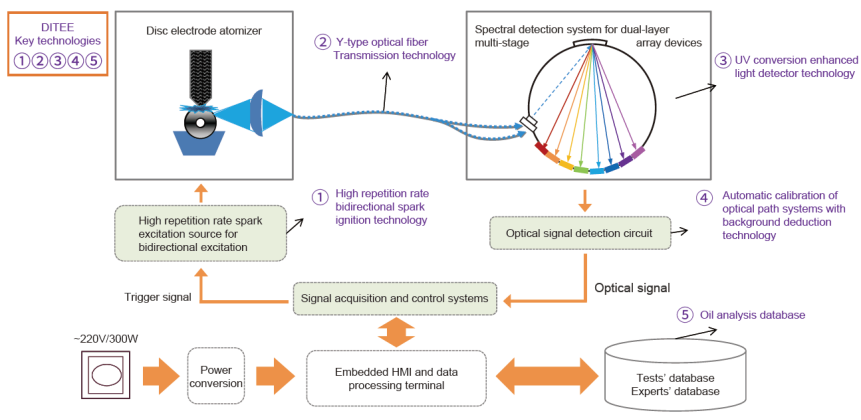

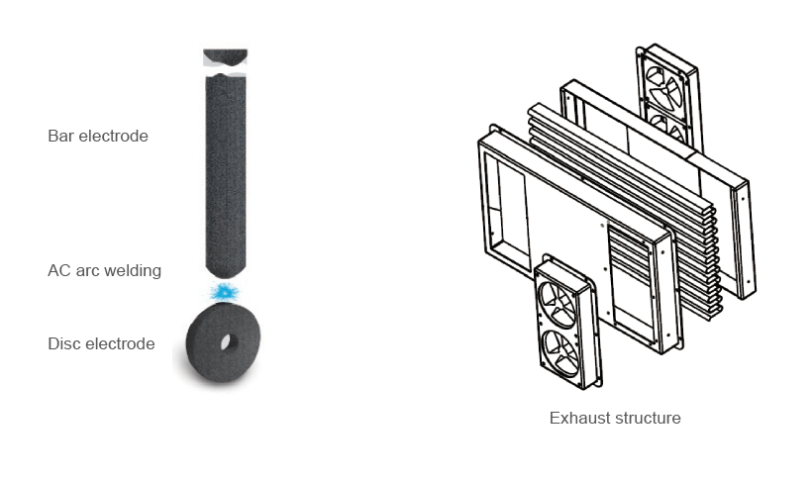

The Oil Analysis Spectrometer is Mainly Composed of Excitation System, Optical System and Readout System

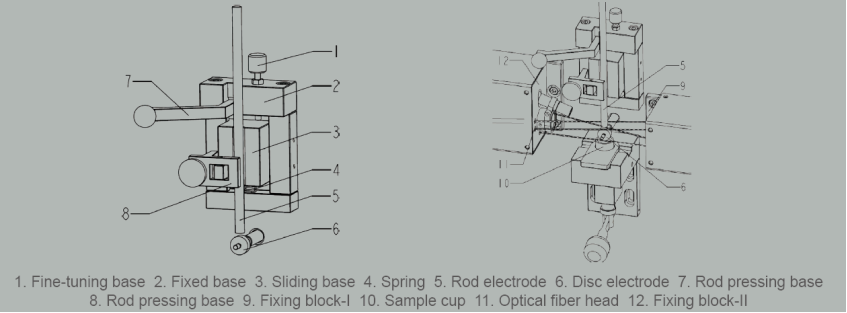

The arc or spark generated by the discharge of the excitation system directly acts on the oil sample to be tested, and the outer electrons of the element are excited to generate characteristic spectral lines. The graphite disk electrode continuously rotates to bring the oil between the counter electrodes. There is a huge potential difference between the graphite disk electrode and the rod electrode. When the potential difference between the electrodes reaches the discharge state, a high voltage discharge occurs at the gap between the counter electrodes, generating an arc or spark, providing an instantaneous high temperature, which makes the oil sample on the disk electrode burn, and the oil sample will be burned, vaporized and plasma-i zed. The instantaneous high temperature in the discharge gap, can fully excite various elements in the oil sample and produces many stable emission spectra. The spectral signal is flexibly introduced into the Roland circle spectroscopic system through the UV optical fiber.

The optical system uses the grating on the Roland circle to collect and split the characteristic spectral lines of the excited elements (the larger the focal length is, the more grating lines are available; and the higher the resolution is, the better the spectroscopic effect will be); the detector receives and photo-electrically converts all characteristic spectral lines.

The readout system periodically reads the charges on the detector and converts them to digital signals, including the intensity of the characteristic spectral lines of elements, because the intensity is proportional to the element concentration, the readout system uses the external standard method to analyze, process and output the data to obtain the content of the detected elements.

Monitoring Significance

Features

The oil analysis spectrometers have been used for a long time, the oil monitoring equipment is not only widely recognized by various military customers, industrial customers and commercial oil laboratories, but also a reliable and effective oil monitoring technology; it can not only realized the condition monitoring of key-oil-equipment, but also be used for the quality control of oil products.

Equipped with scanner, be able to scan the bar code of the sample instead of inputing the corresponding sample information

Due to the intergrated design of the shaft, no need to do the alignment if no faults (no displacement)

Due to the wavelength differences, we equipped with two optical fibers, right one for measure the lithium, calcium and sodium, whith the left side is for measuring the rest elements

Operator is also able to create the application base on the real demands by himself, no need to be authorized by the manufacturer

It is suitable for the simultaneous determination of multiple elements of various metal elements, such as wear metals, pollutants and additives in oils

The standard configuration simultaneously determines 24 elements, including Ag, Al, Ba, Ca, Cd, Cr, Cu, Fe, K, Li, Mg, Mn, Mo, Na, Ni, P, Pb, Sb, Si, Sn, Ti, V, Zn and Bi. Detection channels can be flexibly increased according to different needs, when adding analysis target elements, no hardware changes are required.

Built-in working curve

It is needless to pretreat the samples, direct injection, ~40s for a single test, the testing-time is adjustable, the results will be obtained after only one measurement.

Low cost of use, the consumable materials includes only the standard graphite disc electrodes, bar electrodes,sample cups.

Uses not ceramic but spectrally pure graphite material as the disc electrode.

Using concentrated optical fiber to ensure the resolution of the instrument.

The light chamber is equipped with a closed isolation heat exchanger to effectively prevent dust, water mist and oil mist from invading.

It includes exhaust structure, prevention of cross-contamination.

Neither argon gas nor cooling water is needed.

Integrated fully closed frame structure design, impact resistance, deformation resistance;

Software

Expert spectral analysis software is not only easy to be operated, but also includes the following functions:

The detection is done with the press of a button

With the built-in working curve, it can work normally after simple calibration with standard reference oil

Dynamic drift correction to improve the stability of the optical system

It has export and automatic storage functions

Automatic pixel calibration (spectral tracing)

Working curve correction

Reference line setting

Spectral lines were automatically selected

Measuring range of Different Kinds of Samples

No. | Element | Lubricant & Heavy Fuel Oil | Lubricant Extended Cal | Fuel | Low Detection Fuel | Coolant | Water |

1 | Aluminum (Al) | 0~1000 | 0~1000 | 0~900 | 0~100 | 0~50 | 0~10 |

2 | Barium (Ba) | 0~1000 | 0~6000 |

| 0~100 |

|

|

3 | Boron (B) | 0~1000 | 0~1000 |

| 0~100 |

|

|

4 | Cadmium (Cd) | 0~1000 | 0~1000 |

| 0~100 |

| 0~10 |

5 | Calcium (Ca) | 0~6000 | 0~20000 | 0~900 | 0~100 | 0~50 | 0~10 |

6 | Chromium (Cr) | 0~1000 | 0~1000 | 0~900 | 0~100 |

| 0~10 |

7 | Copper (Cu) | 0~1000 | 0~1000 | 0~900 | 0~100 | 0~50 | 0~10 |

8 | Iron (Fe) | 0~1000 | 0~1000 | 0~900 | 0~100 | 0~50 | 0~10 |

9 | Lead (Pb) | 0~1000 | 0~1000 | 0~900 | 0~100 | 0~50 | 0~10 |

10 | Magnesium (Mg) | 0~2000 | 0~6000 | 0~2700 | 0~100 | 0~50 | 0~10 |

11 | Manganese (Mn) | 0~1000 | 0~1000 | 0~900 | 0~100 |

| 0~10 |

12 | Molybdenum (Mo) | 0~1000 | 0~1000 |

| 0~100 | 0~500 |

|

13 | Nickel (Ni) | 0~1000 | 0~1000 | 0~900 | 0~100 |

| 0~10 |

14 | Phosphorus (P) | 0~2000 | 0~6000 |

| 0~100 | 0~2500 |

|

15 | Silicon (Si) | 0~1000 | 0~1000 | 0~900 | 0~100 | 0~500 | 0~10 |

16 | Silver (Ag) | 0~1000 | 0~1000 |

| 0~100 |

|

|

17 | Sodium (Na) | 0~1000 | 0~6000 | 0~100 | 0~100 | 0~1000 | 0~10 |

18 | Tin (Sn) | 0~1000 | 0~1000 |

| 0~100 |

| 0~10 |

19 | Titanium (Ti) | 0~1000 | 0~1000 |

| 0~100 |

|

|

20 | Vanadium (V) | 0~1000 | 0~1000 | 0~900 | 0~100 |

|

|

21 | Zinc (Zn) | 0~2000 | 0~6000 | 0~900 | 0~100 |

|

|

22 | Potassium (K) | 0~1000 | 0~1000 | 0~900 | 0~100 | 0~1000 | 0~10 |

23 | Lithium (Li) | 0~1000 | 0~1000 |

| 0~100 |

|

|

24 | Antimony (Sb) | 0~1000 | 0~1000 |

|

|

|

|

Technical parameters

Optical system

Optical system: Pashen-Runge, Roland circle optical structure, Roland focal length: 500mm

High-performance holographic diffraction grating, Grating notching 2700L/mm

Optical resolution: 0.006nm

Spectral range: 190-900nm

Double chamber system:

Short wave chamber wavelength:190~470nm

Long wave chamber wavelength: 470~900nm

Both Roland circle and the host machine are equipped with a constant temperature system to maintain constant temperature independently, 40±1°C; the constant temperature is adjustable, which is effectively suitable for too high or too low environment temperature condition

Detector

Cluster optical fiber signal transmission dual-layer, multi-CCD detection spectrum system

The linear array of multiple CCDS is arranged in a Roland circular shape, which realizes continuous and simultaneous detection of the whole band, and facilitates later development of other elements

High performance CCD detector, each CCD with 3648 pixels

Ultraviolet band spectral enhancement detection technol-ogy, enhances the ultraviolet band light intensity, and prolongs the life

Excitation light source

Bidirectional high performance excitation light source, 14000V ignition pulse, digital discharge parameter setting, digital pulse generator, digital offline pulse control

Dual-phase zero-crossing signal detection technology, avoiding high-voltage spark electromagnetic compatibility interference, and improving voltage stability

Excitation chamber

Rod electrode holder for automatic adjustment of electrode pole distance device, ensure that the height of electrode spacing is consistent for all measurements

The excitation room has a visual window, which can visualize the whole excitation process

Complete safety monitoring and protection functions, including excitation chamber door safety lock, sample cup, disc electrode, rod electrode, spark gap sensing monitoring device (laser light source automatic position-ing), with safety alarm and automatic flameout function, so as to ensure user safety.

Semi-permeable cutoff to prevent oil sputtering contami-nation and filter stray light.

Aluminum fire extinguishing device, to prevent volatile sample ablation to produce flames.

Computer system

Operating system: Instrument control and data manage-ment software based on Windows platform

External connection of the control computer

Power Supply and Environment Requirements

Power: 220V±10%, 50/60Hz, AC power, Built-in pressure stabilizing device, no special grounding device is required

Power consumption: ≤1kwFusing current: 16A

The range of operating temperature: -40~50℃

The variation allowance of the maximum temperature: ±5℃/h

Operating humidity: 0~90%, no condensation

Working altitude: ≤7000m

Size and Weight

Size: 740mm(length) X560mm(width) X360mm(height)

Weight: 69kg