-

ASTM D874 Sulfated Ash From Lubricating Oils And Additives

The sample is ignited and burned until only ash and carbon remain. After cooling, the residue is treated with sulfuric acid and heated at 775°C until oxidation of carbon is complete. The ash is then cooled, re-treated with sulfuric acid, and heated at 775°C to constant weight.

Send Email Details -

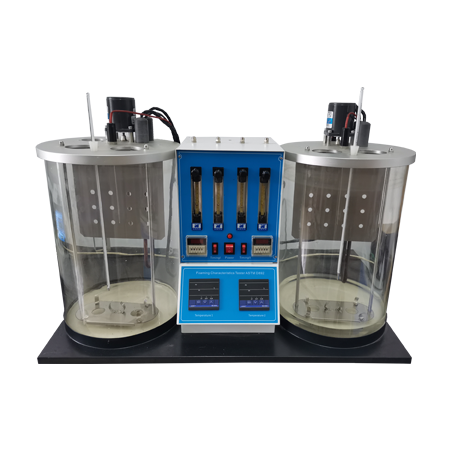

ASTM D892 Foaming Characteristics Of Lubricating Oils

The tendency of oils to foam can be a serious problem in systems such as high-speed gearing, high-volume pumping, and splash lubrication. Inadequate lubrication, cavitation, and overflow loss of lubricant can lead to mechanical failure. This test method is used in the evaluation of oils for such operating conditions.

Send Email Details -

ASTM D665 Rust Preventing Characteristics Of Inhibited Mineral Oil

A mixture of 300 mL of the oil under test is stirred with 30 mL of distilled water or synthetic sea water, as required, at a temperature of 60 6 1°C (140 6 2°F) with a cylindrical steel test rod completely immersed therein. It is recommended to run the test for 4 h; however, the test period may, at the discretion of the contracting parties, be for a shorter or longer period. The test rod is observed for signs of rusting and, if desired, degree of rusting.

Send Email Details -

ASTM D1401 Manual Water Separability Of Petroleum Oils And Synthetic Fluids

This tester provides a guide for determining the water separation characteristics of oils subject to water contamination and turbulence. It is used for specification of new oils and monitoring of in-service oils.

Send Email Details -

ASTM D446 Full Automatic Viscometer Cleanser

This Ultrasonic capillary viscometer cleaner is used for cleaning the capillary viscometers,such as opaque, routine, Ubbelohde, or Pinkevitch viscometers.

Send Email Details