-

ASTM D4603 Inherent Viscosity Apparatus for PET Polyester

KN-4603 Inherent Viscosity Apparatus for PET Polyester conforms the ASTM D4603 Inherent Viscosity Apparatus for PET Polyester. It is used to test the of liquid petroleum products, both transparent and opaque. It used for the determination of the inherent viscosity of poly (ethylene terephthalate) (PET) soluble at 0.50% concentration in a 60/40 phenol/1,1,2,2-tetrachloroethane solution by means of a glass capillary viscometer. Highly crystalline forms of PET that are not soluble in thsi solvent mixture will require a different procedure.

Send Email Details -

ASTM D5293 Apparent Viscosity By Cold Cranking Simulator CCS

The CCS apparent viscosity of automotive engine oils correlates with low temperature engine cranking. CCS apparent viscosity is not suitable for predicting low temperature flow to the engine oil pump and oil distribution system. Engine cranking data were measured by the Coordinating Research CouncilThe measurement of the cranking viscosity of base stocks is typically done to determine their suitability for use in engine oil formulations. A significant number of the calibration oils for this met

Send Email Details -

ASTM D5293 Automatic Apparent Viscosity By Cold Cranking Simulator CCS

The CCS apparent viscosity of automotive engine oils correlates with low temperature engine cranking. CCS apparent viscosity is not suitable for predicting low temperature flow to the engine oil pump and oil distribution system. Engine cranking data were measured by the Coordinating Research CouncilThe measurement of the cranking viscosity of base stocks is typically done to determine their suitability for use in engine oil formulations. A significant number of the calibration oils for this met

Send Email Details -

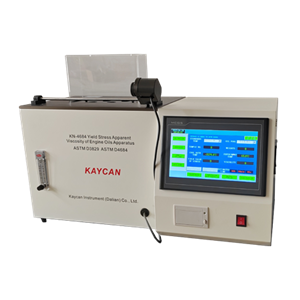

ASTM D4684 Yield Stress And Apparent Viscosity Of Engine Oils

An engine oil sample is held at 80°C and then cooled at a programmed cooling rate to a final test temperature and held for a specified time period. At the end of this period, a series of increasing low torques are applied to the rotor shaft until rotation occurs to determine the yield stress, if any is exhibited. A higher torque is then applied to determine the apparent viscosity of the sample.

Send Email Details -

ASTM D1092 Apparatus for Apparent Viscosity of Lubricating Grease

KN-1092 Apparatus for Apparent Viscosity of Lubricating Grease conforms to ASTM D1092 Standard Test Method for Measuring Apparent Viscosity of Lubricating Grease. This Test method covers measurement, in poises, of the apparent viscosity of lubricating greases in the temperature range from -54℃ to 38℃ (-65℉ to 100℉). Measurements are limited to the range from 25P to 100000P at 0.1s-1 and 1P to 100P at 15000s-1. Apparent viscosity versus shear rate information can be useful in predicting pressure drops in grease distribution systems under steady-state flow conditions at constant temperature.

Send Email Details -

ASTM D5481 Apparent Viscosity At High Temperature And High Shear Rate By Multicell Capillary Viscometer HTHS

High-Temperature and High-Shear Rate Apparent Viscosity Tester (HTHS) covers the laboratory determination of high-temperature high-shear (HTHS) viscosity of engine oil at a temperature of 150℃ using a multicell capillary viscometer containing pressure, temperature, and timing instrumentation. The shear rate for this test method corresponds to an apparent shear rate at the wall of 1.4 million reciprocal seconds (1.4 3 106s-1).This shear rate has been found to decrease the discrepancy between this

Send Email Details -

Hot

ASTM D4683 Viscosity At High Temperature And High Shear Rate By Tapered Plug Viscometer

KN-4683 Apparatus for Viscosity by TBS conforms to ASTM D4683 Standard Test Method for Measuring Viscosity of New and Used Engine Oils at High Shear Rate and High Temperature by Tapered Bearing Simulator Viscometer at 150 °C and ASTM D4741 Standard Test Method for Measuring Viscosity at High Temperature and High Shear Rate by Tapered-Plug Viscometer. The ASTM D4683 covers the laboratory determination of the viscosity of engine oils at 150℃ and 1.0·106s-1 using a viscometer having a slightly tape

Send Email Details -

ASTM D2170 Viscosity Of Asphalts By Vacuum Capillary Viscometer

the kinematic viscosity characterizes flow behavior. the method is used to determine the consistency of bitumen as one element in establishing the uniformity of shipments or sources of supply. the specifications are usually at temperature of 60 and 135℃.

Send Email Details