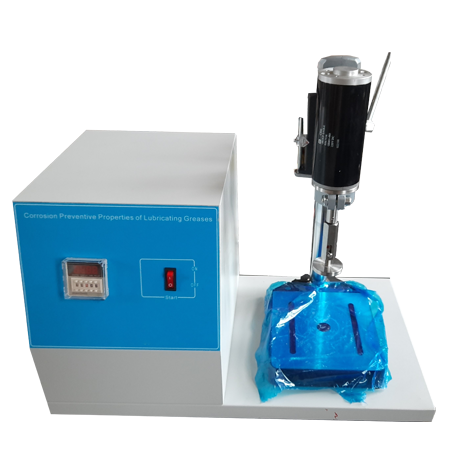

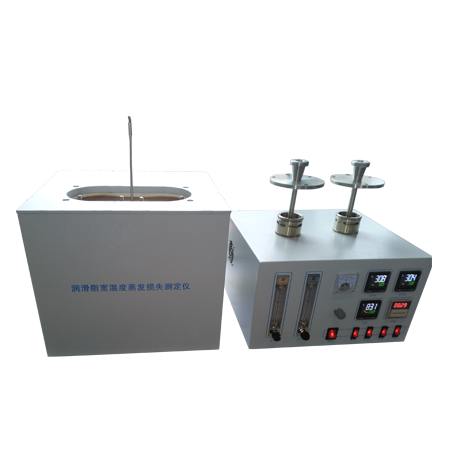

ASTM D1743 Corrosion Preventive Properties Of Lubricating Greases

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets per month

New, cleaned, and lubricated bearings are run under a light thrust load for 60 6 3 s to distribute the lubricant in a pattern that might be found in service. The bearings are exposed to water, then stored for 48 6 0.5 h at 52 6 1°C (125

6 2°F) and 100 % relative humidity. After cleaning, the bearing cups are examined for evidence of corrosion

KN-1743 Corrosion Preventive Properties of Lubricating Greases

Overview

The apparatus conforms to ASTM D1743 Standard Test Method for Determining Corrosion Preventive Properties of Lubricating Greases, it is used for determination of the corrosion preventive properties of greases using grease-lubricated tapered roller bearings stored under wet conditions. This test method is based on CRC Technique L 412 that shows correlations between laboratory results and service for grease lubricated aircraft wheel bearings

Test introduction

New, cleaned, and lubricated bearings are run under a light thrust load for 60 6 3 s to distribute the lubricant in a pattern that might be found in service. The bearings are exposed to water, then stored for 48 6 0.5 h at 52 6 1°C (125 6 2°F) and 100 % relative humidity. After cleaning, the bearing cups are examined for evidence of corrosion

the instrument consists of motor, Thrust loader, transmission gear, bearing bracket and etc. it features compact structure and convenient operation

Technical Parameters:

1.Rated voltage:AC220V±20V 50Hz

2.Motor specification:1450rpm、1750rpm 184W

3.Dimension:400×408×233mm