ASTM D1754 Thin Film Oven Test

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets per month

this oven indicates approximate change in properties of asphalt during conventional hot-mixing at about 150℃ as indicated by viscosity,penetration,or ductility measurement,it yields a residue which approximates the asphalt condition as incorporated in the pavement. if the mixing temperature differs appreciably from the 150℃ level,more or less effect pm properties will occurs

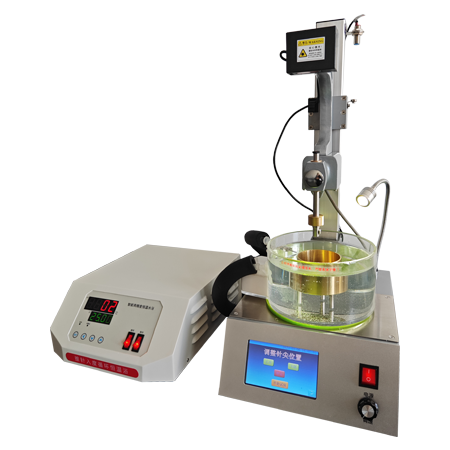

KN-1754 Thin Film Oven

Overview

KN-1754 Thin Film Oven is designed on the requirements of the instrument according to ASTM D1754 Standard Test Method for Effects of Heat and Air on Asphaltic Materials (Thin-Film Oven Test). This oven is used to indicate approximate change in properties of asphalt during conventional hot-mixing at about 150℃ as indicated by viscosity, penetration, or ductility measurements. It yields as residue which approximates the asphalt condition as incorporated in the pavement. If the mixing temperature differs appreciably from the 150℃ level, more or less effect on properties will occur.

Features

Adopts thermal insulation layer and duct between the studio and box shell

Stable and accurate temperature control

Filled with aluminum silicate cotton in insulation

Dedicated air machine to supply the required air flow during the test

Temperature sensor of the heating device adopts the advanced ASIC chip and manufacturing technology with perfect performance

Technical Parameters

Heating power: 2KW

Working temperature: 163℃

Temperature accuracy: ±1℃

Thermometer: 155~170℃, 0.5℃

Wheel speed: 5.5±1rpm

Studio size: 420*450*350

External form size: 820*540*600

Rated voltage: 220V±5%, 50Hz