ASTM D1831 Roll Stability Of Lubricating Grease

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets one month

The roll stability test is widely used in specifications. Test results are significant insofar as they can show a directional change in consistency that could occur in service. No accurate correlation is established between the test resultsand shear stability in actual service.

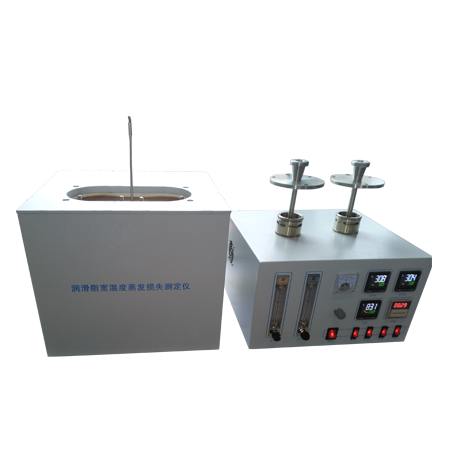

KN-1831 Roll stability Apparatus for Lubricating Grease

Overview

KN-1831 Roll stability Apparatus for Lubricating Grease conforms to ASTM D1831 Standard Test Method for Roll Stability of Lubricating Grease. Cone penetration of an approximately 50-g aliquot of lubricating grease is determined. The grease is then subjected to low shear at 20 to 35°C(68 to 95°F) for 2h±5min in a standard roll stability apparatus, before the cone penetration is a gain measured. The difference between the cone penetration before working and the cone penetration after is used as a measure of the effect to flow shear working on grease consistency. This apparatus is suitable to test the consistence change of the lubricating grease after working on the roller tester to judge the mechanical shear stability of the lubricating grease.

Features

Stainless steel roller Φ90×180mm 5kg

Idle roller is equipped with locating ring to make the roller work normally

The driving motor is installed on the bottom and keeps the rotate speed at 155 to 180r/min

Gear drive roller

Microcomputer temperature controller, digital display, precision ±5℃ PT100 sensor

Digital timer, record the working time, equipped with buzzer alarm

Temperature controller operation instructions: room temperature to 180℃

Technical parameters

Applicable standard: ASTM D1831

Heating method: electric heating circle heats

Time method: digital timer

Temperature control range: room temperature to 180℃

Motor speed: 155 to 180r/min

Unit of work: 2 units

Rated voltage: AC220V/50Hz