ASTM D217 Motorized Grease Worker

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets per month

Cone penetration test results provide one measure of the consistency of a grease. Worked penetration results are required to determine to which NLGI consistency grade a grease belongs. Undisturbed penetration results provide a means of evaluating the effect of storage conditions on grease consistency

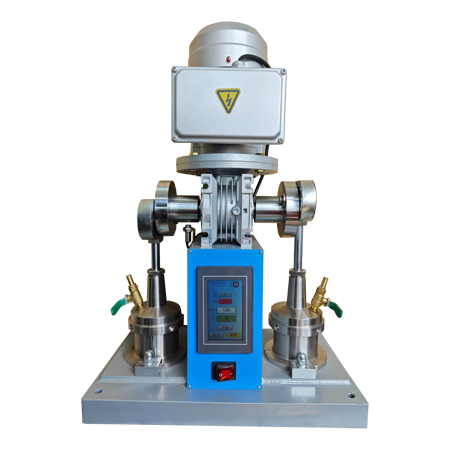

KN-217G Motorized Grease Worker

Overview

KN-217G Motorized Grease Worker conforms to ASTM D217 Standard Test Methods for Cone Penetration of Lubricating Grease. It is suitable for shearing the lubricating grease automatically. Mechanical Grease Workers - For "worked penetration" and "prolonged worked penetration" tests to determine consistency of lubricating greases. This grease worker consists of single or dual steel ASTM grease workers mounted on a sturdy base and driven by a powerful gear reduction motor and meets ASTM specifications for stroke length and rate. It is also equipped with a presetting electronic counter that automatically shuts off the drive motor after any desired number of strokes up to 99,999. Steel grease workers have threaded cup and cover, and steel plunger plate with shaft and handle that connects to eccentric cam on drive unit. Accessory dial thermometer inserts in plated vent cock. Spring loaded tightening clamps hold grease workers securely on base, and steel pins in base facilitate disassembly of grease workers after testing.

Penetration tests are performed on petroleum products to determine consistency and shear stability (lubricating greases) for design, quality control and identification purposes. A standard cone or needle is released from a penetrometer and allowed to drop freely into the sample for 5 seconds (or a different specified interval) at constant temperature. The depth of penetration of the cone or needle into the sample is measured in tenths of a millimeter by the penetrometer.

Features & Parameters

Motor: Horizontal single-phase capacitor starting motor. The rated voltage is 220V, the power is 370W, and the speed is 1400 rpm. It is connected with the turbo reducer through the coupling.

Coupling: A plum-shaped elastic coupling is used to connect the reducer and the motor.

Turbo reducer: double output shaft reducer. The transmission ratio is 25:1, and a pair of eccentric mechanisms are installed on the turbine shaft at both ends of the reducer

Worker: Installed on the frame on both sides of the reducer, driven by the motor through the coupling through the eccentric mechanism of the reducer, and works continuously at about 60 movements per minute.

Counting display: 5-inch color LCD touch screen. When selecting the number of computer relays, use the wave switch to arbitrarily set a number (time), when the number reaches the set value, it can drive the relay to work and cut off the motor power. This worker is a double-acting reciprocating test equipment. It consists of a motor coupling, a reducer, an eccentric mechanism, a worker and a machine base.

The computer real-time monitors the motor temperature and torque parameters, so as to protect the motor from damage.

It has the function of monitoring the ambient temperature. The screen will indicate a prompt, if the temperature exceeds the test range of 15-30°C.

Non-oil reduction gearbox