ASTM D4048 Copper Corrosion From Lubricating Grease

Brand KN

Product origin Dalian,China

Delivery time deliver as soon as received payment

Supply capacity 30 sets one month

A prepared copper strip is totally immersed in a sample of grease and heated in an oven or liquid bath at a specified

temperature for a definite period of time. Commonly used conditions are 100 6 1°C (212 6 2°F) for 24 h 6 5 min. At the end of this heating period, the strip is removed, washed, and compared with the Copper Strip Corrosion Standard.

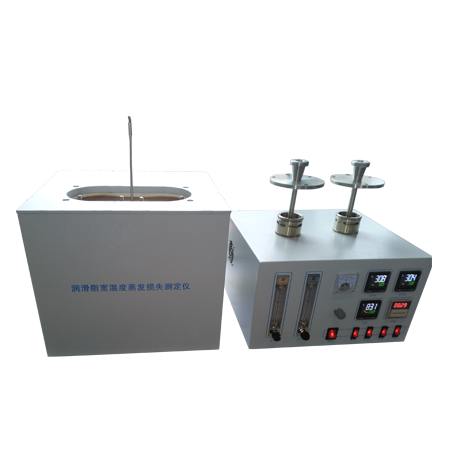

KN-4048 Grease Copper Strip Corrosion Apparatus

Overview

KN-4048 Grease Copper Strip Corrosion Apparatus conforms to ASTM D4048 Standard Test Method for Detection of Copper Corrosion from Lubricating Grease. It can measure the tendency of lubricating grease to corrode copper under specific static conditions. It may be of some value in predicting possible chemical attack on lubricated parts, such as bearings that contain copper or copper alloys. Such corrosion, for example, can cause premature bearing failures. However, no correlations with actual field service, most of which are under dynamic conditions, have been established. It does not measure either the ability of the lubricant to inhibit copper corrosion caused by factors other than the lubricant itself nor does it measure the stability of the grease in the presence of copper.

Summary of test method

A prepared piece of copper strip is fully immersed in the grease sample and heated in an oven or liquid bath for 24 hours at 100℃. At the end of the test, take out the copper strip and wash, Method A is to compare the test copper strip with the corrosion standard color scale to determine the corrosion level. Method B is to check whether the copper strip has discoloration.

Features

1. Liquid bath, bath material is aluminum alloy, do not need the conduction oil during the test

2. Heating tube adopts the internal heating

3. Platinum resistance sensor, controlled by digital display temperature controller

4. Equipped with auxiliary heater for fast heating speed

5. Digital display temperature controller is convenient to temperature correction

Technical parameters

1. Input power<1850W

2. Main heating power: 1000W

3. Auxiliary heating power: 800W

4. Rated voltage: AC220V±10%, 50Hz

5. Temperature range: Ambient~150℃±0.2℃

6. Test station: 4