-

ASTM D4693 Low-Temperature Torque Tester

KN-4693 Low-Temperature Torque Tester conforms to ASTM D4693 Standard Test Method for Low-Temperature Torque of Grease-Lubricated Wheel Bearings. This test method covers the determination of the extent to which a test grease retards the rotation of a specially-manufactured, spring-loaded, automotive-type wheel bearing assembly when subjected to low temperatures. Torque values, calculated from restraining-force determinations, are a measure of the viscos resistance of the grease. This test method was developed with greases giving torques of less than 35N·m at 40℃

Send Email Details -

ASTM D1478 Low-Temperature Torque Tester

KN-1478 Low-Temperature Torque Tester conforms to ASTM D1478 Standard Test Method for Low-Temperature Torque of Ball Bearing Grease. This test method was developed using greases having very low torque characteristics at -54℃. Specifications for greases of this type commonly require testing at this temperature. Specifications for greases of other types can require testing at temperatures from -73℃ to -18℃. This test method has proved helpful in the selection of greases for low-powered mechanisms, such as instrument bearings used in aerospace applications. The suitability of this test method for other applications requiring different greases, speeds, and temperatures should be determined on an individual basis.

Send Email Details -

ASTM D2265 Automatic High Temperature Dropping Point Apparatus

KN-2265Z Automatic High Temperature Dropping Point Apparatus conforms to the ASTM D2265 Standard Test Method for Dropping Point of Lubricating Grease Over Wide Temperature Range. This apparatus covers the determination of the dropping point of lubricating grease and it tests dropping points of lubricating greases at temperatures of up to 400°C.

Send Email Details -

Automatic Penetration Tester

Automatic Penetration tester is used for not only evaluating the consistency of lubricating greases and wax ,but also evaluate the needle penetration for bitumen products.

Send Email Details -

ASTM D566 Dropping Point Of Lubricating Grease

the dropping point is the temperature at which the grease passes from a semisolid to a liquid state under the conditions of test.

Send Email Details -

ASTM D972 Evaporation Loss For Lubricating Grease

The loss of volatile materials from greases and oils can adversely effect the original performance characteristics of a lubricant and therefore could be a significant factor in evaluating a lubricant for a specific use. Such volatiles can also be considered contaminants in the environment in which the lubricant is to be used. Correlation between results from this test method and service performance has not been established.

Send Email Details -

ASTM D1831 Roll Stability Of Lubricating Grease

The roll stability test is widely used in specifications. Test results are significant insofar as they can show a directional change in consistency that could occur in service. No accurate correlation is established between the test resultsand shear stability in actual service.

Send Email Details -

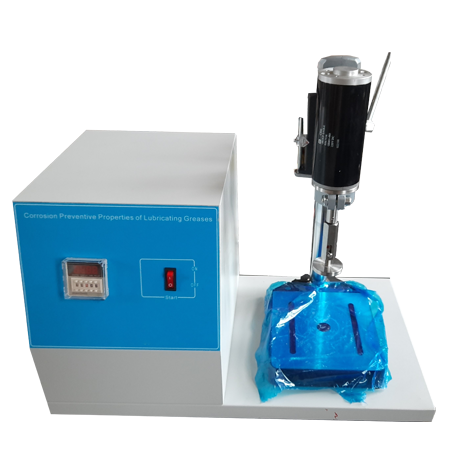

ASTM D6138 Corrosion Preventive Properties Of Lubricating Greases

New, cleaned, and lubricated bearings are tested partially immersed in water (distilled, synthetic sea water, or sodium chloride solution) under no applied load at a speed of 83 6 5 rpm in a predetermined sequence of running and stopping for a period of approximately one week. After cleaning, the bearing rings are examined and rated according to the degree of corrosion

Send Email Details -

ASTM D1743 Corrosion Preventive Properties Of Lubricating Greases

New, cleaned, and lubricated bearings are run under a light thrust load for 60 6 3 s to distribute the lubricant in a pattern that might be found in service. The bearings are exposed to water, then stored for 48 6 0.5 h at 52 6 1°C (125 6 2°F) and 100 % relative humidity. After cleaning, the bearing cups are examined for evidence of corrosion

Send Email Details -

ASTM D1263 Leakage Tendencies Of Automotive Wheel Bearing Greases

The test method provides a screening device that permits differentiation among products having distinctly different leakage characteristics. It is not the equivalent oflongtime service tests, nor is it intended to distinguish between wheel bearing greases showing similar or borderline leakage

Send Email Details -

ASTM D4290 Leakage Tendencies Of Automotive Wheel Bearing Grease

This apparatus differentiates among wheel bearing greases having distinctly different high-temperature leakage characteristics. It is not the equivalent of longtime service tests

Send Email Details -

Hot

ASTM D2265 High Temperature Dropping Point Apparatus

The dropping point is useful to assist in identifying the grease as to type and for establishing and maintaining bench marks for quality control. The results are to be considered to have only limited significance with respect to service performance because dropping point is a static test.

Send Email Details