-

-

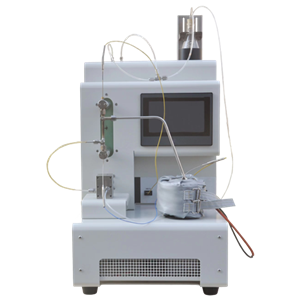

ASTM D971 Automatic Oil Surface Tensiometer

KN-971 conforms to ASTM D971 Standard Test Method for Interfacial Tension of Oil Against Water by the Ring Method. It can be used to replace chemical method with physical method, and can be used to measure the surface tension value of a variety of liquid quickly and accurately.KN-971 can also be separated from the use of the computer, built in LCD digital display and small printer, can be stand alone operation, can also be connected to the computer control to observe the dynamic changes in tension curve.

Send Email Details -

Brookfield Viscometer

Using a coaxial center structure, using a small sample adapter, each measurement requires a very small sample size, temperature control quickly and accurately. It has many measuring parameters, rich display content, convenient operation, intuitive reading, high measuring precision, stable rotational speed, strong anti-interference performance, wide working voltage and so on. can replace the same type of imported instrument

Send Email Details -

Gel Permeation Chromatography (GPC)

GPC gel purification system has many advantages such as high purification rate, simple operation, convenient maintenance, safety and reliability. It is mainly used in the pre-treatment and purification process of samples for the detection of pesticide and veterinary drug residues, polycyclic aromatic hydrocarbons, and polychlorinated biphenyls. It is widely used in the fields of agricultural products, food, environment and life sciences.

Send Email Details -

Portable Chiller

KN-ZL Portable Chiller can be widely used in petroleum, chemical, pharmaceutical, biochemical, scientific research and other fields. This is a very popular cooling device in the world.

Send Email Details -

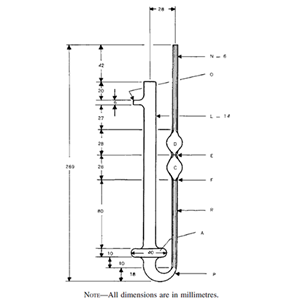

ASTM D611 Manual Aniline Point And Mixed Aniline Point Round type

The aniline point (or mixed aniline point) is useful as an aid in the characterization of pure hydrocarbons and in the analysis of hydrocarbon mixtures

Send Email Details -

ASTM D7097 Thermo-Oxidation Engine Oil Simulation Tester

KN-7097 Thermo-Oxidation Engine Oil Simulation Tester conforms to ASTM D7097 Standard Test Method for Determination of Moderately High Temperature Piston Deposits by Thermo-Oxidation Engine Oil Simulation Test—TEOST MHT and ASTM D6355 Standard Test Method for Determination of High Temperature Deposits by Thermo-Oxidation Engine Oil Simulation Test. Deposit-forming tendencies of an engine oil under oxidative conditions are determined by circulating an oil-catalyst mixture comprising a small sample of the oil and a very small (0.1g) amount of an organo-metallic catalyst. This sample mixture is then circulated for exactly 24h in the TEOST MHT instrument over a special wire-wound depositor rod heated by electrical current to a controlled temperature of 285℃ at the hottest location on the rod. The depositor rod is weighed before and after the test and any deposit formation on the rod as well as any deposits collected from rod washings are determined. During the test, precisely controlled and directed air is caused to bathe the oil flowing down the depositor rod and, thereby, to provide opportunity for oxidation. Precision of the test is strongly influenced by the care in manufacture of the wire-wound steel depositor rods and the treatment of the coating of the wound wire, the rate of air flow, and the amount and degree of mixing of the catalyst.

Send Email Details -

KN-NIR Near Infrared Spectrometer

KN-NIR Near Infrared Spectrometer adopts advanced MEMS Fourier transform technology. Optional spectral range of the instrument (1300nm~2600nm, 1150~1700nm, 1250~2100nm) meets the needs in testing multiple indicators and research. High signal to noise ratio is possible to analyze the parameters of low content of the sample. Built in wavelength calibration to ensure smaller difference between stations difference and better long-term stability. The tester equipped with a temperature control device, which can improve the data stability.

Send Email Details