-

ASTM D611 Manual Aniline Point And Mixed Aniline Point Round type

The aniline point (or mixed aniline point) is useful as an aid in the characterization of pure hydrocarbons and in the analysis of hydrocarbon mixtures

Send Email Details -

ASTM D7097 Thermo-Oxidation Engine Oil Simulation Tester

KN-7097 Thermo-Oxidation Engine Oil Simulation Tester conforms to ASTM D7097 Standard Test Method for Determination of Moderately High Temperature Piston Deposits by Thermo-Oxidation Engine Oil Simulation Test—TEOST MHT and ASTM D6355 Standard Test Method for Determination of High Temperature Deposits by Thermo-Oxidation Engine Oil Simulation Test. Deposit-forming tendencies of an engine oil under oxidative conditions are determined by circulating an oil-catalyst mixture comprising a small sample of the oil and a very small (0.1g) amount of an organo-metallic catalyst. This sample mixture is then circulated for exactly 24h in the TEOST MHT instrument over a special wire-wound depositor rod heated by electrical current to a controlled temperature of 285℃ at the hottest location on the rod. The depositor rod is weighed before and after the test and any deposit formation on the rod as well as any deposits collected from rod washings are determined. During the test, precisely controlled and directed air is caused to bathe the oil flowing down the depositor rod and, thereby, to provide opportunity for oxidation. Precision of the test is strongly influenced by the care in manufacture of the wire-wound steel depositor rods and the treatment of the coating of the wound wire, the rate of air flow, and the amount and degree of mixing of the catalyst.

Send Email Details -

KN-NIR Near Infrared Spectrometer

KN-NIR Near Infrared Spectrometer adopts advanced MEMS Fourier transform technology. Optional spectral range of the instrument (1300nm~2600nm, 1150~1700nm, 1250~2100nm) meets the needs in testing multiple indicators and research. High signal to noise ratio is possible to analyze the parameters of low content of the sample. Built in wavelength calibration to ensure smaller difference between stations difference and better long-term stability. The tester equipped with a temperature control device, which can improve the data stability.

Send Email Details -

ASTM D6481 Portable Energy Dissipation X-ray Fluorescence Spectrometer

KN-6481 Portable Energy Dissipation X-ray Fluorescence Spectrometer conforms to ASTM D6481 Standard Test Method for Determination of Phosphorus, Sulfur, Calcium, and Zinc in Lubrication Oils by Energy Dispersive X-ray Fluorescence Spectroscopy and ASTM D7751 Standard Test Method for Determination of Additive Elements in Lubricating Oils by EDXRF Analysis. This tester is used to test metal elements in oils like P, S, Cl, Ca, Ti, V, Cr, Mn, Fe, Ni, Cu Zn, PB, Mo, Ag, Cd, Sn, etc.

Send Email Details -

ASTM D473 Sedimentin Crude Oil By Extraction Method

A knowledge of the sediment content of crude oils and fuel oils is important both to the operation of refining and the buying or selling of these commodities

Send Email Details -

Hot

ASTM D3948 Water Separation Characteristics Of Aviation Turbine Fuels

This tester provides a measure of the presence of surfactants in aviation turbine fuels. it can detect carryover traces of refinery treating residues in fuel as produced. They can also detect surface active substances added to or picked up by the fuel during handling from point of production to point of use. Certain additives can also have an adverse effect on the rating. Some of these substances affect the ability of filter separators to separate free water from the fuel.

Send Email Details -

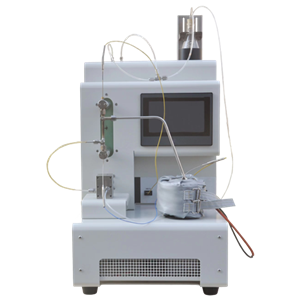

High-Frequency Infrared Carbon & Sulfur Analyzer

KN-8820 Infrared carbon and sulfur analyzer is used in conjunction with the high-frequency furnace, which can quickly and accurately determine the mass fraction of carbon and sulfur in steel, iron and its alloys, non-ferrous metals, cement, ore, glass, coke, coal, catalyst and other solid materials. It is a new technology product integrating optical, mechanical, electrical, computer and analysis technology, with the characteristics of wide measurement range and accurate and reliable analysis results. Using stable computer technology, the intelligence of the instrument, the collection and processing of the graphics, text and data displayed on the screen have reached the current high level in China, and it is an ideal analysis equipment for the determination of carbon and sulfur in many industries.

Send Email Details -

ASTM D1881 Foaming Tendencies Of Engine Coolants In Glassware

The test method generally will distinguish coolants that have a tendency to foam excessively from those that are suitable for further evalution to determine performance in actual service

Send Email Details