ASTM D6377 Apparatus for Vapor Pressure of Crude Oil

Brand KN

Product origin DALIAN

Delivery time 30 DAYS AFTER PAYMENT

Supply capacity 10 SETS/MONTH

KN-6377 Apparatus for Vapor Pressure of Crude Oil conforms to ASTM D6377 Standard Test Method for Determination of Vapor Pressure of Crude Oil: VPCRX (Expansion Method). Employing a measuring chamber with a built-in piston, a sample of known volume is drawn from the sample container into the temperature controlled chamber at 20℃ or higher. After sealing the chamber, the volume produces the desired V/L value. The temperature of the measuring chamber is then regulated to the measuring temperature. After the temperature and pressure equilibrium, the measured pressure is recorded as the VPCRX of the sample. The test specimen shall be mixed during the measuring procedure by shaking the measuring chamber to achieve pressure equilibrium in a reasonable time of 5 to 30min. For results related to Test Method D323, the final volume of the measuring chamber shall be five times the test specimen volume and the measuring temperature shall be 37.8℃.

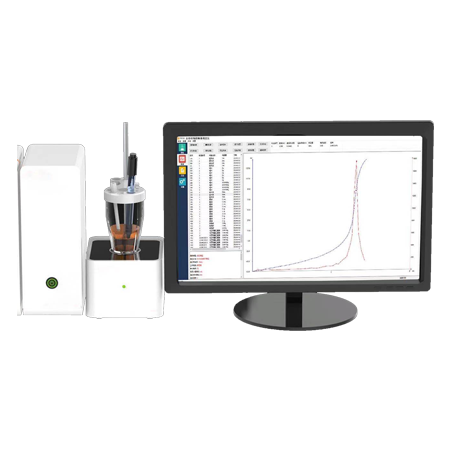

KN-6377 Apparatus for Vapor Pressure of Crude Oil

Overview

KN-6377 Apparatus for Vapor Pressure of Crude Oil conforms to ASTM D6377 Standard Test Method for Determination of Vapor Pressure of Crude Oil: VPCRX (Expansion Method). Employing a measuring chamber with a built-in piston, a sample of known volume is drawn from the sample container into the temperature controlled chamber at 20℃ or higher. After sealing the chamber, the volume produces the desired V/L value. The temperature of the measuring chamber is then regulated to the measuring temperature. After the temperature and pressure equilibrium, the measured pressure is recorded as the VPCRX of the sample. The test specimen shall be mixed during the measuring procedure by shaking the measuring chamber to achieve pressure equilibrium in a reasonable time of 5 to 30min. For results related to Test Method D323, the final volume of the measuring chamber shall be five times the test specimen volume and the measuring temperature shall be 37.8℃.

Features

Adopts a computer to control the test process automatically, the screen displays the current pressure and the current temperature of the measuring chamber in real time, automatically completes the entire test process and saves the results, and the results can be viewed and printed at any time.

Only 1ml sample is required for test

Adopts semiconductor Peltier device for cooling and heating, fast response, no vibration and no noise

Small size, light in weight and easy to operate.

After the test, the apparatus will automatically alarm, prompting the operator that the test is over, and an error alarm will occur; it can be connected to the LIMS and printer through the PC

Technical parameters

Control: PC automatic control, displays the real time pressure and temperature

Injection mode: Automatic, built-in piston

Heating & Cooling: Semiconductor chip

Pressure range: 0~200kPa

Pressure accuracy: 0.1kPa

Sample volume: 10ml (includes cleaning and testing)

Temperature controller: Imported digital display controller

Temperature control range: 0~100℃, 0.1℃