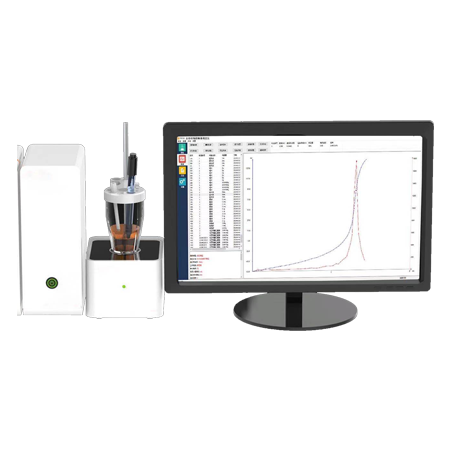

ASTM D8288 Automatic Tapping Torque Testing System

Brand KN

Product origin DALIAN

Delivery time 30 DAYS AFTER PAYMENT

Supply capacity 10 SETS/MONTH

KN-8288 Automatic Tapping Torque Testing System conforms to ASTM D8288 Standard Test Method for Comparison of Metal working Fluids Using a Tapping Torque Test Machine. This test method can be used to predict the comparative lubricating properties of a metalworking fluid (MWF).

Fluids that produce lower torques or higher efficiencies are predicted to have better machining characteristics. The method is applicable to all tap types, machining speeds, alloys and coatings that can be fabricated into a test piece. Comparison between different operating conditions or various types of fluids can be made. The reportable quantity is the efficiency or mean average torque of a reference fluid divided by the mean average torque of the fluid of interest.

KN-8288 Automatic Tapping Torque Testing System

Overview

KN-8288 Automatic Tapping Torque Testing System conforms to ASTM D8288 Standard Test Method for Comparison of Metal working Fluids Using a Tapping Torque Test Machine. This test method can be used to predict the comparative lubricating properties of a metalworking fluid (MWF).

Fluids that produce lower torques or higher efficiencies are predicted to have better machining characteristics. The method is applicable to all tap types, machining speeds, alloys and coatings that can be fabricated into a test piece. Comparison between different operating conditions or various types of fluids can be made. The reportable quantity is the efficiency or mean average torque of a reference fluid divided by the mean average torque of the fluid of interest.

Features

1. Reversible control servo motor, with high rotation precision, quieter operation

2. Dynamic data collection up to 100000 readings per second

3. Multiple button control, supports manual, automatic control and motor torque maximum protection

4. Touch screen operation, integrated PC (8 operating system languages)

5. Marble base and main column

6. Collet-type chuck + quick change head (head adjustable for taps ranging M2-M10)

7. Automatic torque protection when torque exceeds 10N, preventing overload damage to the equipment

8. Servo AC power supply stabilization system: Integrates purification, stabilization, and automatic protection. Features a wide stabilization range, high stabilization precision, and rapid response capabilities

9. This workbench encompasses multiple functions: screen visualization, high-precision XY-axis grating scales, aluminum alloy with multiple failure treatments for resistance to deformation and excellent rigidity. It maintains dynamic geometric error precision within 1μm. The workbench also supports manual fine-tuning for more precise hole positioning.

Technical parameters

1. Dimension: 660*560*865mm

2. Weight: 135kg

3. Precision Grating Scale: X,Y Axis Travel: 50~3000mm, 0.5um precision

4. Spindle Speed: 50~1000rpm

5. Rated voltage: 220V, 50Hz