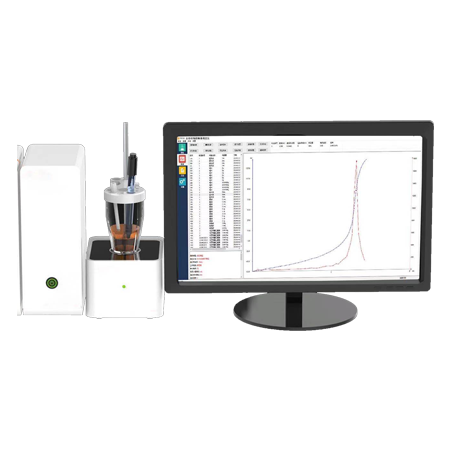

High-Frequency Infrared Carbon & Sulfur Analyzer

Brand KN

Product origin Dalian

Delivery time with 30 days after receiving full payment

Supply capacity 10sets/month

KN-8820 Infrared carbon and sulfur analyzer is used in conjunction with the high-frequency furnace, which can quickly and accurately determine the mass fraction of carbon and sulfur in steel, iron and its alloys, non-ferrous metals, cement, ore, glass, coke, coal, catalyst and other solid materials. It is a new technology product integrating optical, mechanical, electrical, computer and analysis technology, with the characteristics of wide measurement range and accurate and reliable analysis results. Using stable computer technology, the intelligence of the instrument, the collection and processing of the graphics, text and data displayed on the screen have reached the current high level in China, and it is an ideal analysis equipment for the determination of carbon and sulfur in many industries.

KN-8820 High Frequency Infrared Carbon & Sulfur Analyzer

Summary

KN-8820 Infrared carbon and sulfur analyzer is used in conjunction with the high-frequency furnace, which can quickly and accurately determine the mass fraction of carbon and sulfur in steel, iron and its alloys, non-ferrous metals, cement, ore, glass, coke, coal, catalyst and other solid materials. It is a new technology product integrating optical, mechanical, electrical, computer and analysis technology, with the characteristics of wide measurement range and accurate and reliable analysis results. Using stable computer technology, the intelligence of the instrument, the collection and processing of the graphics, text and data displayed on the screen have reached the current high level in China, and it is an ideal analysis equipment for the determination of carbon and sulfur in many industries.

Linear calibration in full scale range, linear without inflection points. Adopts gravimetric linear compensation technology, which can achieve good stability of non-quantitative weighing. No less than 16 carbon-sulfur channels, program heating function, through the software can achieve high-frequency furnace temperature control. When do the data statistics, it is able to select the analysis results which are needed to participate in the operation. Software will automatically calculates the average value, standard deviation, relative standard deviation. Self-diagnosis function: real-time monitoring of gas circuit, high-frequency furnace and detector, timely alarm in case of error; Multi-level management capabilities.

Standard Reference

ISO 15350 Steel and iron - Determination of total carbon and sulfur content - Infrared absorption method after combustion in an induction furnace (routine method)

ISO 9556 Steel and iron - Determination of total carbon content - Infrared absorption method after combustion in an induction furnace

ISO 4935 Steel and iron -- Determination of sulfur content -- Infrared absorption method after combustion in an induction furnace

High Frequency Furnace

The high-frequency circuit design adopts high-power high-frequency air-cooled ceramic power tube, ceramic vacuum capacitor (100A), and non-inductive resistance to improve the stability of the high-frequency combustion system

The frequency of the high-frequency desktop induction furnace is 20MHz, the power is 2.7KVA, and the maximum adjustment is 5KVA

The self-excited directional coupler takes power feedback to ensure that the output power is consistent, so that the sample can be fully burned, and with good stability.

Adopts software control to automatically detect the working conditions of solenoid valves, lifting cylinders and high-frequency furnaces, with self-diagnosis and protection functions, automatically alarms in case of errors, and can be diagnosed remotely.

Automatic overtime/overcurrent alarm: ensures the HF furnace works properly

The cast aluminum integrated forming furnace body and gold processing are used to effectively prevent air leakage caused by the assembly

High-precision electronic flow meter (supply oxygen under constant pressure ) is used to control and analyze the gas flow, and the analysis results are stable and reliable

Automatic double helix cleaning the dust on the furnace head, three-layer baffle anti-splash design, improve measurement accuracy

Constant temperature water removal device in the furnace

Automatic high-pressure dust discharge function, dedicated dust discharge channel, reduce air path blockage; The dust filtration device developed by powder metallurgy materials is installed in the stove, and the combustion chamber and dust filter are automatically cleaned twice per analysis, and the dust is automatically sucked to prevent the adsorption effect of dust on the analysis process

Multiple filtration in the gas path, and platinum-silicon catalyst, magnesium perchlorate and sodium hydroxide three-in-one additives are used as filter purification agents to ensure that the gas chamber will not be polluted for a long time.

Infrared Analysis System

The electronic circuit adopts modular design, it features stable and reliable, and adopts multi-level concealed isolation circuit to completely solve high-frequency interference

Power supply: Adopts high-quality linear integrated military-grade module power supply, stable output, no fault.

Adopts imported infrared light cut stepper motor, special new antioxidant platinum infrared light source, high efficiency, stable spectral characteristics, with tens of thousands of hours service life

The optical band emitted by the light source is limited to 2-10um at the source to ensure no stray light; Enter the subsequent detection channel to ensure the stability and accuracy of detection; The concentrating device inside the light source ensures the parallelism of the outgoing light; The inside of the light source is filled with protective gas to protect the stability of the light source and prevent oxidation

Equipped with independent four gold-plated infrared detection cells (high and low carbon cell, high and low sulfur cell) to automatically switch base on the different contents

The use of low-noise, high-sensitivity, high-stability pyroelectric solid-state infrared detector (Allif) ensures the precision and accuracy of the measurement

Standard samples can be used for single-point or multi-point correction, which is convenient and practical

Windows full English menu operation, the test software is fully functional, and there is no obstacle for any operator

The newly equipped remote diagnosis and positioning software system can remotely monitor the use and stability of equipment, once there is some problems, it will notify operators immediately, and remotely deal with all faults caused by operating software, so as to save a lot of time for maintenance

Brand computer control and precision electronic analytical balance, non-quantitative weighing, etc. all ensure the stability of operation and data reliability

The software has complete functions, providing more than 40 functions such as file help, system monitoring, channel selection, data statistics, result correction, breakpoint correction, automatic leak detection of system diagnosis, and outdated overcurrent alarm

The optical fiber data transmission system is adopted to avoid the interference problems caused by conventional RS232 interface transmission caused by high-frequency vibration, and greatly improve the communication speed

Equipped with high-precision gas flow controller, automatic control of gas flow, it will not be affected by environment, temperature or pressure, metal double ferrules connection, good air tightness. Equipped with Swiss infrared modulation motor. Also equipped with ultra-microporous metal filter (0.4 um)

Technical Parameters

Measuring range

Low carbon content: 0.00001~4% | High carbon content: 4%~99.9999% |

Low sulfur content: 0.00001~1% | High Sulfur content: 1%~99.9999% |

2. Accuracy: Meets the ISO 15350 requirements

3. Precision & Repeatability:

Carbon measurement conforms to ISO 9556, RSD≤5% or 1ppm |

Sulfur measurement conforms to ISO 4935, RSD≤1% or 1ppm |

4. Sensitivity (readout accuracy): 0.01ppm

5. Analysis time: 25~60s adjustable, generally will be about 35s

6. Minimum readout: 0.00001%

7. Electronic balance: Accuracy±0.1mg, sensitivity: 100g/0.1mg

8. Gas flow:

Top blowing oxygen flow rate: 0.1~2.0L/min |

Analytical gas flow rate: 3.0~4.0L/min |

9. Max power: 2.7KW

10. Analytical absorption cell

Gold-plated carbon-sulfur analysis cell and high-precision pyroelectric infrared detector |

The analytical cell signal will be tracked during the whole process and automatically adjusted |

11. Desiccant: High-efficiency color-changing desiccant

12. Filtration and purification agent (special materials need to be used): sodium hydroxide, magnesium perchlorate, platinum-silicon catalyst

13. HF furnace dimension: 52*65*94cm

Packing list

Item | Quantity | Remark |

High Frequency Furnace | 1 set | KN |

Infrared absorber | 1 set | KN |

Data connection system | 1 set | Multi-level shielded sensing data cable |

Infrared analysis software | 1 set | HW(5) software system |

Analytical balance | 1 set | BSM120.4 |

PC | 1 set | Lenovo |

Oxygen reducing valve | 1 pc | |

Tungsten particle | 1 bottle | |

PU tube | 5 meters | |

Ceramic crucible (ultralow carbon content) | 1 box | |

Dust discharge tube | 1 pc | |

Quartz tube | 1 pc | |

Button switch | 2 pcs | |

Vacuum grease | 1 box | |

Oxygen connector | 1 pc | |

Fuse | 2 pcs | |

Discoloration desiccant | 1 bottle | |

Tweezers for crucible | 1 pc | |

Small brush | 2 pcs | |

Power cord | 1 pc | |

Screw driver | 2 pcs | |

Tool pliers | 1 pc | |

Sample spoon | 2 pcs | |

Electroprobe | 1 pcs |