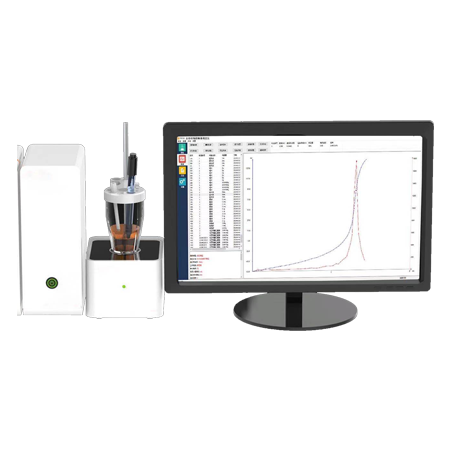

ASTM D381 Existent Gum Content Tester

Brand KN

Product origin DALIAN

Delivery time 30 days after receiving full payment

Supply capacity 30 sets a month

KN-381 Existent Gum Content Tester (Steam Method) conforms to ASTM D381 Standard Test Method for Gum Content by Jet Evaporation. When testing either aviation or motor gasoline, a 50±0.5ml quantity of fuel is evaporated under controlled conditions of temperature and flow of air. When testing aviation turbine fuel, a 50±0.5ml quantity of fuel is evaporated under controlled conditions of temperature an flow of steam. For aviation gasoline and aviation turbine fuel, the resulting residue is weighed and reported as milligrams per 100ml. For motor gasoline, the residue is weighed before and after extracting with heptane and the results reported as milligrams per 100ml.

KN-381 Existent Gum Content Tester (Steam Method)

Overview

KN-381 Existent Gum Content Tester (Steam Method) conforms to ASTM D381 Standard Test Method for Gum Content by Jet Evaporation. When testing either aviation or motor gasoline, a 50±0.5ml quantity of fuel is evaporated under controlled conditions of temperature and flow of air. When testing aviation turbine fuel, a 50±0.5ml quantity of fuel is evaporated under controlled conditions of temperature an flow of steam. For aviation gasoline and aviation turbine fuel, the resulting residue is weighed and reported as milligrams per 100ml. For motor gasoline, the residue is weighed before and after extracting with heptane and the results reported as milligrams per 100ml.

Features

Tester consists of temperature controller, timing device, heating device, manometer, flow meter, metal bath and steam generator

The temperature control device adopts a digital display temperature controller, which has high precision. The output adopts solid state relay, it features non-contact, no spark, no noise, long service life, safe and reliable

Digital timing device

Stainless steel heating, it features fast heating speed

Adopts metal bath, reliable and stable

Technical parameters

Rated voltage: AC220V±10%, 50Hz

Power: 2500W

Steam generator power: 8kW

Temperature control mode: Digital controller

Evaporation bath temperature: 232~246℃

Test station: 3

Air flow rate: 600±90ml/s

Ambient requirements

Temperature, 10~50℃, Humidity≤85%