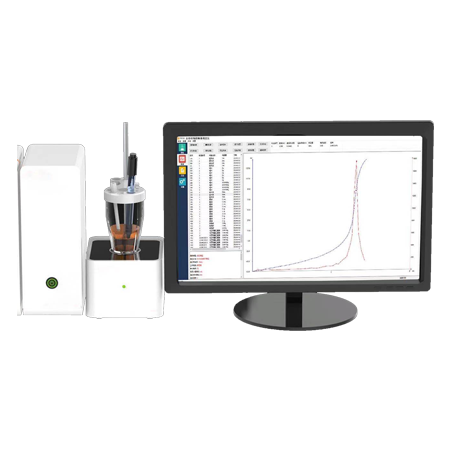

ASTM D6421 Apparatus for Electronic Port Fuel Injector Fouling by Bench Procedure

Brand KN

Product origin DALIAN

Delivery time 30 sets after receiving full payment

Supply capacity 30 sets a month

KN-6421 Apparatus for Electronic Port Fuel Injector Fouling by Bench Procedure conforms to ASTM D6421 Standard Test Method for Evaluating Automotive Spark-Ignition Engine Fuel for Electronic Port Fuel Injector Fouling by Bench Procedure. This test method covers a bench test procedure to evaluate the tendency of automotive spark-ignition engine fuel to foul electronic port fuel injectors (PFI). The test method utilizes a bench apparatus equipped with Bosch injectors specified for use in a 1985-1987 Chrysler 2.2-L turbocharged engine. This test method is based on a test procedure developed by the Coordinating Research Council (CRC) for prediction of the tendency of spark-ignition engine fuel to form deposits in the small metering clearances of injectors in a port fuel injection engine.

KN-6421 Apparatus for Electronic Port Fuel Injector Fouling by Bench Procedure

Overview

KN-6421 Apparatus for Electronic Port Fuel Injector Fouling by Bench Procedure conforms to ASTM D6421 Standard Test Method for Evaluating Automotive Spark-Ignition Engine Fuel for Electronic Port Fuel Injector Fouling by Bench Procedure. This test method covers a bench test procedure to evaluate the tendency of automotive spark-ignition engine fuel to foul electronic port fuel injectors (PFI). The test method utilizes a bench apparatus equipped with Bosch injectors specified for use in a 1985-1987 Chrysler 2.2-L turbocharged engine. This test method is based on a test procedure developed by the Coordinating Research Council (CRC) for prediction of the tendency of spark-ignition engine fuel to form deposits in the small metering clearances of injectors in a port fuel injection engine.

Features

After preparation is done, one button operation, and the tester will record the test results automatically

Dedicated data processing software to automatically read in test data, automatically calculate test results and output test records

There will be guidance operation during the preparation process

Be able to save no less than 10 pieces of test data

If there is a something happens that may causes the result invalid during the test process, the tester will automatically stop and alarm

The tester has with nozzle automatic screening function, which can complete the nozzle screening operation required by the standard

Adopts high precision balance and maintenance-free pump

Equipped with dedicated ultrasonic cleaning system to clean the nozzle

Technical parameters

Injection temperature: 160±5℃

Injection pressure: constant at 263±6.8kPa

Injection pulse time: 15±1s, accuracy: 0.1s

Oil tank capacity: 2.25L

Cycle definition: 15s Injection pulse (repeat continuously 4ms high and 20ms low) + 50min hot soak +10 min cool down period

Cycle number: 22 cycle a time

Balance accuracy: 0.01g

Ambient temperature: 10~35℃

Relative humidity: 20~80% 10.Rated voltage: AC220V±10%, 50Hz, 1000W