-

ASTM D92 Automatic Cleveland Open Cup Flash Point Tester

Flash point can indicate the possible presence of highly volatile and flammable materials in a relatively nonvolatile or nonflammable material. For example, an abnormally low flash point on a test specimen of engine oil can indicate gasoline contamination

Send Email Details -

Manual Pensky-Martens Closed Cup Flash Point Tester

The flash point temperature is one measure of the tendency of the test specimen to form a flammable mixture with air under controlled laboratory conditions. It is only one of a number of properties which must be considered in assessing the overall flammability hazard of a material

Send Email Details -

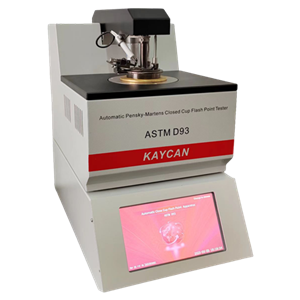

Automaitc Pensky-Martens Closed Cup Flash Point Tester

The flash point temperature is one measure of the tendency of the test specimen to form a flammable mixture with air under controlled laboratory conditions. It is only one of a number of properties which must be considered in assessing the overall flammability hazard of a material

Send Email Details -

ASTM D56 Tag Closed Cup Flash Point Tester

this apparatus conforms to ASTM D56 Standard Test Method for Flash Point by Tag Closed Cup Tester, it is used for flash point determinations of liquids with a viscosity of below 5.5 centistokes (cSt) at 104℉ (40℃) or below 9.5cSt at 77℉ (25℃),

Send Email Details -

IP170 Abel Flash Point Tester

This International Standard specifies a method for the determination of the closed cup flash point of petroleum products and other liquids having flash points between -30℃ and 70℃ inclusive.

Send Email Details -

ISO 13736 Automatic Abel Closed Cup Flash Point Tester

KN-170Z Automatic Abel Closed Cup Flash Point Tester conforms to IP170 Petroleum products and other liquids -- Determination of flash point -- Abel closed cup method and ISO 13736 Petroleum Products and Other Liquids - Determination of Flash Point - Abel Closed Cup Method and IP170 Determination of flash point - Abel closed-cup method. This International Standard specifies a method for the determination of the closed cup flash point of petroleum products and other liquids having flash points between -30℃ and 70℃ inclusive. However, the precision given for the method is only valid for flash points in the range -5℃ to 66.5℃. This standard is not acceptable to water borne paints which may however be tested using ISO 3679

Send Email Details -

ASTM D3828 Small Scale Closed Cup Flash Point Tester

KN-3828 Small Scale Closed Cup Flash Point Tester conforms to ASTM D3828 Standard Test Methods for Flash Point by Small Scale Closed Cup Tester. Flash point measures the response of the test specimen to heat an ignition source under controlled laboratory conditions. It is only one of a number of properties that must be considered in assessing the overall flammability hazard of a material. Flash point is used in shipping and safety regulations to define flammable and combustible materials and classify them. Consult the particular regulation involved for precise definitions of these classes. Flash point can indicate the possible presence of highly volatile and flammable materials in a relatively nonvolatile or nonflammable material.

Send Email Details -

ASTM D5001 Ball-on-Cylinder Lubricity Evaluator (BOCLE)

KN-5001 Ball-on-Cylinder Lubricity Evaluator (BOCLE) conforms to ASTM D5001 Standard Test Method for Measurement of Lubricity of Aviation Turbine Fuels by the Ball-on-Cylinder Lubricity Evaluator (BOCLE) and ASTM D6078 Standard Test Method for Evaluating Lubricity of Diesel Fuels by the Scuffing Load Ball-on-Cylinder Lubricity Evaluator (SLBOCLE).. The fluid under test is placed in a test reservoir in which atmospheric air is maintained at 10% relative humidity. A non-rotating steel ball is held in a vertically mounted chuck and forced against the outside diameter of an axially mounted cylindrical steel ring with an applied load. The test ring is rotated at a fixed speed while being partially immersed in the fluid reservoir. This maintains the ring in a wet condition and continuously transports the test fluid to the ball/ring interface. The wear scar generated on the test ball is a measure of the lubricating property of the fluid.

Send Email Details