-

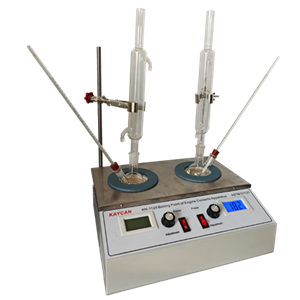

ASTM D1120 Boiling Point Of Engine Coolants

The equilibrium boiling point indicates the temperature at which the sample will start to boil in a cooling system under equilibrium conditions at atmospheric pressure.

Send Email Details -

ASTM D566 Dropping Point Of Lubricating Grease

the dropping point is the temperature at which the grease passes from a semisolid to a liquid state under the conditions of test.

Send Email Details -

Analytical Balance

l Weighing units (g, ct, ozt, oz, gn, dwt, 1b) l Counting (Reference numbers 1/10/20/50/100) l Tare function over 100% of the capacity l Automatic calibration (external) l Below weighting on hook l Adjustable feed l Spirit level

Send Email Details -

ISO 6617 Ageing Characteristics Tester

The oxidation stability test of mineral transformer oils is a method for assessing the amount of sludge and acid products formed in a transformer oil when the oil is tested under prescribed conditions. Good oxidation stability is necessary in order to maximize the service life of the oil by minimizing the formation of sludge and acid.

Send Email Details -

ASTM D1881 Foaming Tendencies Of Engine Coolants In Glassware

The test method generally will distinguish coolants that have a tendency to foam excessively from those that are suitable for further evalution to determine performance in actual service

Send Email Details -

KN-40A Channel Point Tester for Gear Oil

KN-40A Channel Point Tester for Gear Oil conforms to FTMS-791B-3465.1 and SH/T 0030. It is used for determination of channel point of gear oil at low temperature. The test consists of storing an Oil sample for 18 hours at a low temperature, cutting a channel in the lubricants with a metal strip and determining whether the lubricants flow together to covet the bottom of the container within 10 seconds.

Send Email Details -

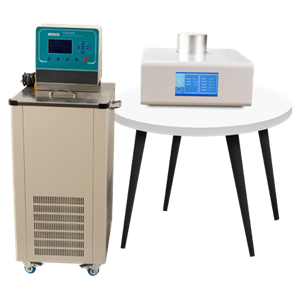

ASTM D4419 Low Temperature Differential Scanning Calorimeter

KN-4419 Low Temperature Differential Scanning Calorimeter conforms to ASTM D4419 Standard Test Method for Measurement of Transition Temperatures of Petroleum Waxes by Differential Scanning Calorimetry (DSC). DSC in a convenient and rapid method for determining the temperature limits within which a wax undergoes during transitions. The highest temperature transition is a solid-liquid transition associated with complete melting; it can guide the choice of wax storage and application temperatures. The solid-solid temperature transition is related to the properties of the solid, that is, hardness and blocking temperature.

Send Email Details -

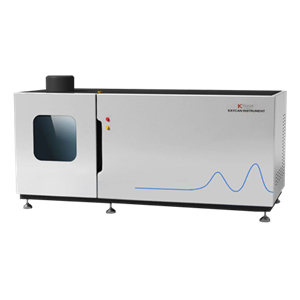

ASTM D4951 Additive Elements In Lubricating Oils By ICP AES

Additive packages are blends of individual additives, which can act as detergents, antioxidants, antiwear agents, and so forth. Many additives contain one or more elements covered by this test method. Additive package specifications are based,in part, on elemental composition. Lubricating oils are typically blends of additive packages, and their specifications are also determined, in part, by elemental composition. This test method can be used to determine if additive packages and unused lubricating oils meet specifications with respect to elemental composition.

Send Email Details