-

ASTM D1319 Hydrocarbon Types In Liquid Petroleum Products

The determination of the total volume % of saturates, olefins, and aromatics in petroleum fractions is important in characterizing the quality of petroleum fractions as gasoline blending components and as feeds to catalytic reforming processes.

Send Email Details -

ASTM D2619 Apparatus for Hydrolytic Stability of Hydraulic Fluids

KN-2619 Apparatus for Hydrolytic Stability of Hydraulic Fluids conforms to ASTM D2619 Standard Test Method for Hydrolytic Stability of Hydraulic Fluids (Beverage Bottle Method). This test method differentiates the relative stability of hydraulic fluids in the presence of water under the conditions of the test. Hydrolytically unstable hydraulic fluids form acidic and insoluble contaminants which can cause hydraulic system malfunctions due to corrosion, valve sticking, or change in viscosity of the fluid. The degree of correlation between this test method and service performance has not been fully determined.

Send Email Details -

Apparatus for Chlorine in Aromatics

KN-7536 Apparatus for Chlorine in Aromatics conforms to ASTM D7536 Standard Test Method for Chlorine in Aromatics by Monochromatic Wavelength Dispersive X-ray Fluorescence Spectrometry. This test method provides for the precise measurement of the chlorine content of aromatics with minimal sample preparation and analyst involvement. The typical time for each analysis is five or ten minutes. Knowledge of the chlorine content of aromatics is important for process control as well as the prediction and control of operational problems such as unit corrosion and catalyst poisoning, and in the blending of products to commodity specifications. Various federal, state, and local agencies regulate the chlorine content of some petroleum products, including aromatics. Unbiased and precise determination of chlorine in aromatics is critical to compliance with regulatory standards.

Send Email Details -

ASTM D6082 High Temperature Foaming Characteristics Of Lubricating Oils

The tendency of oils to foam at high temperature can be a serious problem in systems such as high-speed gearing, high volume pumping, and splash lubrication. Foaming can cause inadequate lubrication, cavitation, and loss of lubricant due to overflow, and these events can lead to mechanical failure

Send Email Details -

Portable Octane And Cetane Tester

Determines the Pump Octane Number (AKI), Research Octane Number (RON), and Motor Octane Number (MON) of unleaded gasoline, ethanol blended gasoline, leaded gasoline and Cetane Number for diesel fuels.

Send Email Details -

ASTM E659 Autoignition Temperature Tester

KN-659 Autoignition Temperature Tester conforms to ASTM E659 Standard Test Method for Autoignition Temperature of Chemicals. A small, metered sample of the product to be tested is inserted into a uniformly heated 500ml glass flask containing air at a predetermined temperature. The contents of the flask are observe in a dark room for 10min following insertion of the sample, or until autoignition occurs. Autoignition is evidenced by the sudden appearance of a flame inside the flask and by a sharp rise in the temperature of the gas mixture. The lowest internal flask temperature at which hot-flame ignition occurs for a series of prescribed sample volumes is taken to be the hot-flame autoignition temperature of the chemical in air at atmospheric pressure. Ignition delay times (ignition time lags) are measured in order to determine the ignition delay-ignition temperature relationship.

Send Email Details -

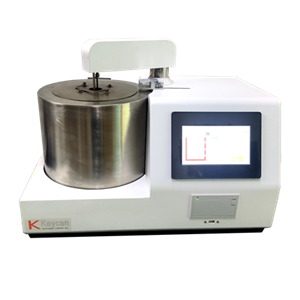

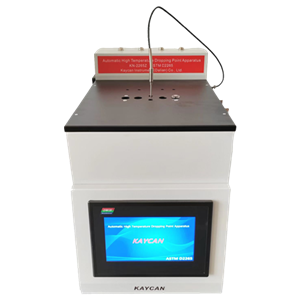

ASTM D2265 Automatic High Temperature Dropping Point Apparatus

KN-2265Z Automatic High Temperature Dropping Point Apparatus conforms to the ASTM D2265 Standard Test Method for Dropping Point of Lubricating Grease Over Wide Temperature Range. This apparatus covers the determination of the dropping point of lubricating grease and it tests dropping points of lubricating greases at temperatures of up to 400°C.

Send Email Details -

ASTM D8288 Automatic Tapping Torque Testing System

KN-8288 Automatic Tapping Torque Testing System conforms to ASTM D8288 Standard Test Method for Comparison of Metal working Fluids Using a Tapping Torque Test Machine. This test method can be used to predict the comparative lubricating properties of a metalworking fluid (MWF). Fluids that produce lower torques or higher efficiencies are predicted to have better machining characteristics. The method is applicable to all tap types, machining speeds, alloys and coatings that can be fabricated into a test piece. Comparison between different operating conditions or various types of fluids can be made. The reportable quantity is the efficiency or mean average torque of a reference fluid divided by the mean average torque of the fluid of interest.

Send Email Details