-

ASTM D6217 Apparatus for Particulate Contamination in Middle Distillate Fuels

KN-6217 Apparatus for Particulate Contamination in Middle Distillate Fuels conforms to ASTM D6217 Standard Test Method for Particulate Contamination in Middle Distillate Fuels by Laboratory Filtration. The mass of particulates present in a fuel is a significant factor, along with the size and nature of the individual particles, in the rapidity with which fuel system filters and other small orifices in fuel systems can become plugged. This test method provides a means of assessing the mass of particulates present in a fuel sample.

Send Email Details -

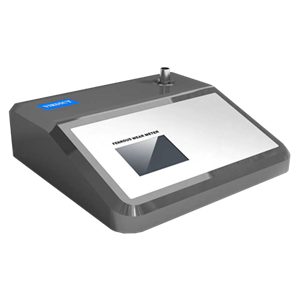

ASTM D8120 Ferrous Wear Meter

KN-8120 Ferrous Wear Meter conforms to ASTM D8120 Standard Test Method for Ferrous Debris Quantification. By quantifying the concentration of total ferrous debris, this test method provides a direct indication of war in the machinery by enabling the user to pinpoint when there is a deviation from the normal buildup of ferrous debris shed by the machinery or when the concentration of ferrous debris has exceeded safe operating limits.

Send Email Details -

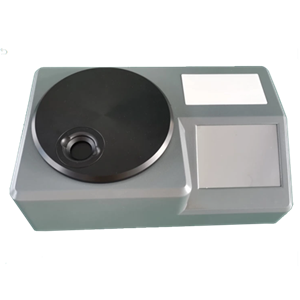

ASTM D8120 Ferrous Debris Quantification Tester

KN-8120Z Ferrous Debris Quantification Tester conforms to ASTM D8120 Standard Test Method for Ferrous Debris Quantification. By quantifying the concentration of total ferrous debris, this test method provides a direct indication of wear in the machinery by enabling the user to pinpoint when there is a deviation from the normal buildup of ferrous debris shed by the machinery or when the concentration of ferrous debris has exceeded safe operating limits.

Send Email Details -

ASTM D8184 Particle Quantifier Instrument for Ferrous Wear Debris

KN-8184 Particle Quantifier Instrument for Ferrous Wear Debris conforms to ASTM D8184 Standard Test Method for Ferrous Wear Debris Monitoring in In-Service Fluids Using a Particle Quantifier Instrument. This test method is intended for the application of PQ magnetometry in assessing the progression of wear in machinery, for example, engines and gearboxes, by trending the mass of ferrous debris in samples of lubricating oils or greases.

Send Email Details -

ASTM D6421 Apparatus for Electronic Port Fuel Injector Fouling by Bench Procedure

KN-6421 Apparatus for Electronic Port Fuel Injector Fouling by Bench Procedure conforms to ASTM D6421 Standard Test Method for Evaluating Automotive Spark-Ignition Engine Fuel for Electronic Port Fuel Injector Fouling by Bench Procedure. This test method covers a bench test procedure to evaluate the tendency of automotive spark-ignition engine fuel to foul electronic port fuel injectors (PFI). The test method utilizes a bench apparatus equipped with Bosch injectors specified for use in a 1985-1987 Chrysler 2.2-L turbocharged engine. This test method is based on a test procedure developed by the Coordinating Research Council (CRC) for prediction of the tendency of spark-ignition engine fuel to form deposits in the small metering clearances of injectors in a port fuel injection engine.

Send Email Details -

ASTM D381 Existent Gum Content Tester

KN-381 Existent Gum Content Tester (Steam Method) conforms to ASTM D381 Standard Test Method for Gum Content by Jet Evaporation. When testing either aviation or motor gasoline, a 50±0.5ml quantity of fuel is evaporated under controlled conditions of temperature and flow of air. When testing aviation turbine fuel, a 50±0.5ml quantity of fuel is evaporated under controlled conditions of temperature an flow of steam. For aviation gasoline and aviation turbine fuel, the resulting residue is weighed and reported as milligrams per 100ml. For motor gasoline, the residue is weighed before and after extracting with heptane and the results reported as milligrams per 100ml.

Send Email Details -

ASTM D381 Existent Gum Content Tester, Air Method

KN-381A Existent Gum Content Tester (Air Method) conforms to ASTM D381 Standard Test Method for Gum Content by Jet Evaporation. When testing motor gasoline, a 50±0.5ml quantity of fuel is evaporated under controlled conditions of temperature and flow of air. For motor gasoline, the residue is weighed before and after extracting with heptane and the results reported as milligrams per 100ml.

Send Email Details -

ASTM D94 Saponification Number Of Petroleum Products

A known mass of the sample is dissolved in a suitable solvent, such as butanone (methylethylketone), xylenes, or Stoddard Solvent, or a combination thereof (Warning— Extremely flammable. Vapors can cause flash fire), and is heated with a known amount of alcoholic potassium hydroxide (KOH). The excess alkali is titrated with standard acid, and the saponification number is calculated.

Send Email Details