-

EN14214 Fatty Acid Methyl Esters For Biodiesel By GC

The biodiesel specified shall be mono-alkyl esters of long chain fatty acids derived from vegetable oils and animal fats.

Send Email Details -

ASTM D1945 Analysis Of Natural Gas By GC

This GC is of significance for providing data for calculating physical properties of the sample, such as heating value and relative density, or for monitoring the concentrations of one or more of the components in a mixture.

Send Email Details -

ASTM D4291 Trace Ethylene Glycol In Used Engine Oil By GC

Leakage of aqueous engine coolant into the crank case weakens the ability of the oil to lubricate. If ethylene glycol is present, it promotes varnish and deposit formation. This test method is designed for early detection to prevent coolant from accumulating and seriously damaging the engine

Send Email Details -

ASTM D4815 Oxygenates In Gasoline By GC

Ethers, alcohols, and other oxygenates can be added to gasoline to increase octane number and to reduce emissions. Type and concentration of various oxygenates are specified and regulated to ensure acceptable commercial gasoline quality. Drivability, vapor pressure, phase separation, exhaust, and evaporative emissions are some of the concerns associated with oxygenated fuels.

Send Email Details -

Hot

AAS Flame Furance

When fuels are combusted, metals present in the fuels can form low melting compounds that are corrosive to metal parts. Metals present at trace levels in petroleum can deactivate catalysts during processing. These test methods provide a means of quantitatively determining the concentrations of vanadium, nickel, iron, and sodium. Thus, these test methods can be used to aid in determining the quality and value of the crude oil and residual oil.

Send Email Details -

Hot

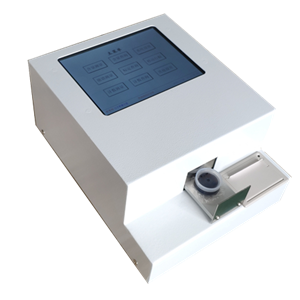

ASTM D4294 Portable EDXRF Sulfur Content

KN-4294A Portable EDXRF Sulfur Analyzer is a complete solution to test and verify adherence to the International Maritime Organization (IMO) Low Sulfur Fuel Oil Standard Requirement in response to the significant reduction of the maximum permissible levels of sulfur in marine fuels from 3.5 % to 0.5 %, as being enforced from the beginning of 2020. KN-4294A is a high performance, portable XRF analyzer that provides the energy industry with the perfect sulfur elemental analysis method for analyzing elemental content in oils such as lubricants, diesel fuels, jet fuels, kerosene, other distillates, volatile oils, residual oils, hydraulic oils, crude oils, unleaded petrol, alcoholic gasoline, biodiesel. Also, it can check the existence of elements content, wear elements, pollutants and sulfur content in other similar petroleum products. It can be used in any place, providing safe, high-quality sulfur content analyzing condition for liquid, solid or gas samples. In line with ASTM D4294 Standard Test Method for Sulfur in Petroleum and Petroleum Products by Energy Dispersive X-ray Fluorescence Spectrometry, ISO8754 Petroleum Products – Determination of Sulfur Content – EDXRF up-to date version and other testing standards

Send Email Details -

ASTM D1266 Sulfur In Petroleum Products Lamp Method

The sample is burned in a closed system, using a suitable lamp (Fig. 1) and an artificial atmosphere composed of 70 % carbon dioxide and 30 % oxygen to prevent formation of nitrogen oxides. The oxides of sulfur are absorbed and oxidized to sulfuric acid by means of hydrogen peroxide solution which is then flushed with air to remove dissolved carbon dioxide. Sulfur as sulfate in the absorbent is determined acidimetrically by titration with standard sodium hydroxide solution, or gravimetrically by precipitation as barium sulfate

Send Email Details -

ASTM D5453 Ultraviolet Fluorescence Sulfur Content

Some process catalysts used in petroleum and chemical refining can be poisoned when trace amounts of sulfur bearing materials are contained in the feedstocks. This test method can be used to determine sulfur in process feeds sulfur in finished products, and can also be used for purposes of regulatory control.

Send Email Details